مطحنة الحبوب الفعالة - طحن الحبوب بسهولة

1316مطحنة حبوب لطحن الحبوب والحبوب بكفاءة، مما يضمن حجم جسيمات موحد ويدعم خطوط إنتاج تجهيز الأغذية والأعلاف.

عرض التفاصيلابحث في المحطة بأكملها

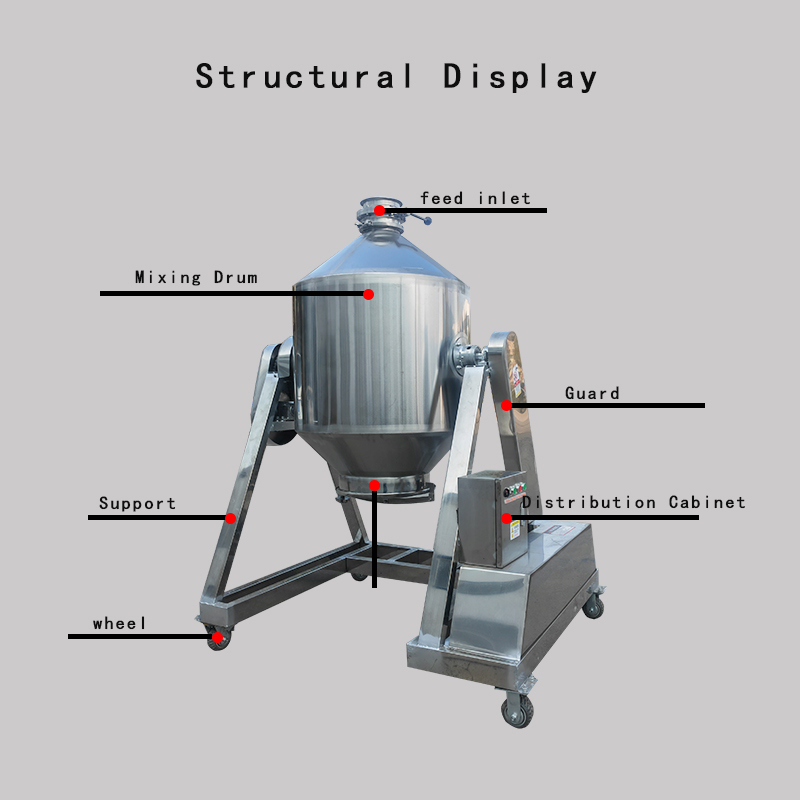

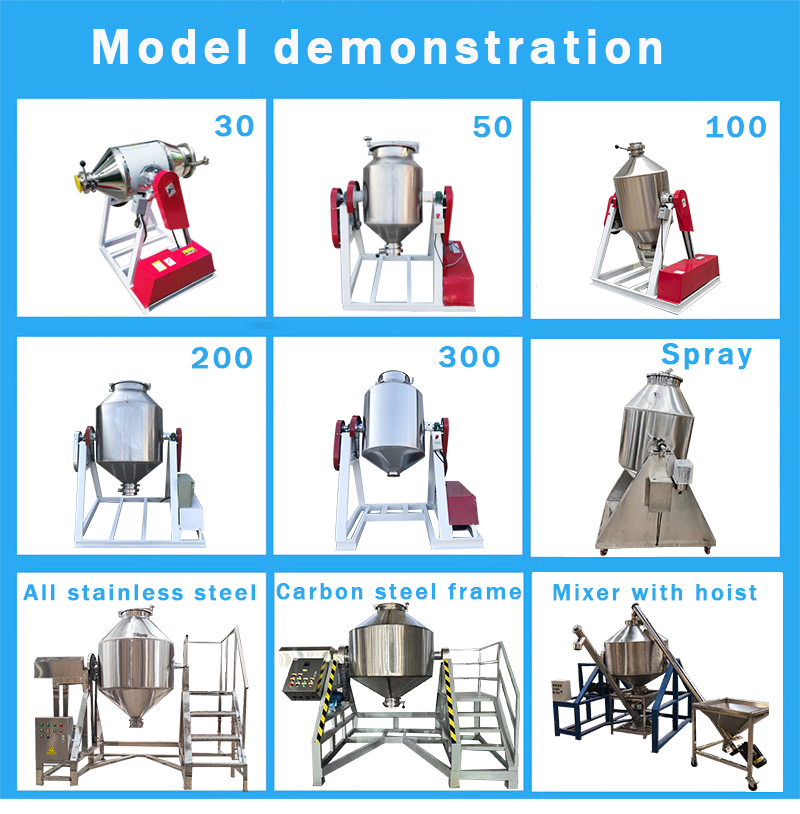

The Stainless Steel Flour Mixer is a drum-type mixer used for blending various powdered raw materials. This mixer offers a high degree of mixing uniformity. Its shape resembles a waist drum, hence it is also called a drum powder mixer or a double-cone powder mixer. Its vertical drum design, combined with specially shaped mixing blades, enables 360-degree dead-angle-free mixing, ensuring that the raw materials are thoroughly blended in a short time.

The Stainless Steel Flour Mixer rotates 360 degrees, tumbling and mixing. Mixing blades are located in the middle of the drum. During operation, the mixing blades rotate simultaneously. The rotating double-cone drum causes the materials inside to tumble and mix chaotically, while the high-speed rotating blades break up any clumps, allowing for rapid and homogeneous mixing within the drum.

Operating Procedures for the Stainless Steel Flour Mixer Pre-Production Preparation

Mixing Operation

A. Check that the drum outlet is closed and ensure it is securely shut. Check the direction of the inlet; the correct position is approximately 45 degrees upward. If it is not in the correct position, start the machine, rotate the drum to the correct position, and then stop the machine.

B. Loosen the fixing screw next to the outlet, open the outlet, and pour the prepared materials into the drum (volume should not exceed 2/3 of the drum’s capacity).

C. Close the outlet and tighten the fixing screw.Mixing:

Start the machine. Move the forward/reverse switch to the right to rotate the drum forward. Start the timer. Control the mixing time based on the volume of materials in the drum—typically 5-10 minutes of forward rotation. Then, return the switch to the center position to stop the drum. After the drum comes to a complete stop, move the switch to the left to rotate the drum in reverse for the same duration. Stop the machine, paying attention to control the drum’s final position so that the outlet faces downward.Applicable Materials

The Stainless Steel Flour Mixer can blend various powdered raw materials, including:

-Flour, rice flour

Spice powders

White sugar, granulated sugar, salt

Glutinous rice flour, pumpkin powder, dumpling flour

Chili powder, Sichuan pepper powder, pepper powder

Star anise powder, bay leaf powder, cumin powder, fennel powder

Starch

Monosodium glutamate (MSG), chicken bouillon powder Food additives

Fruit and vegetable powders, yam powder

Traditional Chinese medicine powders: Panax notoginseng powder, angelica powder, atractylodes powder

Barbecue seasonings, dipping and sprinkling mixes

Whole grain powders, meal replacement powders, nutritional powders

Lily bulb powder, red date powder

Mung bean powder, soybean powder

يمكنها أيضًا خلط المساحيق الكيميائية والمساحيق الصيدلانية والمواد الخام الأخرى.

Maintenance and Care

Daily Cleaning: Clean the mixing drum and blades after each use to prevent material residue and bacterial growth.

Regular Inspection: Periodically check if the tightening screws on the mixing blades are loose and if the belt tension is appropriate.

Gearbox Lubrication: Regularly change or add the specified food-grade lubricant to the reduction gearbox according to the manufacturer’s manual.

Professional Service: If abnormal noise or vibration occurs, stop the machine immediately and have it inspected by qualified personnel.

مطحنة حبوب لطحن الحبوب والحبوب بكفاءة، مما يضمن حجم جسيمات موحد ويدعم خطوط إنتاج تجهيز الأغذية والأعلاف.

عرض التفاصيلمطحنة يانسون نجمي لطحن التوابل بكفاءة عالية وموحدة ومناسبة لخطوط إنتاج الأغذية والأعشاب والتوابل.

عرض التفاصيلخط تكسير كامل للتوابل من أجل معالجة عالية الكفاءة، وحجم جسيمات موحد، وإنتاج أمثل في صناعات الأغذية والتوابل.

عرض التفاصيلمطحنة حبوب الكاكاو مناسبة لتجهيز الشوكولاتة والأغذية والمشروبات، مما يوفر كفاءة عالية وحجم جسيمات موحد ودعم خط الإنتاج.

عرض التفاصيليستخدم هذا الموقع الإلكتروني ملفات تعريف الارتباط لتحسين تجربة تصفحك. من خلال الاستمرار في استخدام هذا الموقع، فإنك توافق على استخدام ملفات تعريف الارتباط الخاصة بنا. تتم معالجة البيانات التي يتم جمعها من هذا الموقع الإلكتروني وتخزينها في الولايات المتحدة.