In food industrial production, the quality of powdered sugar directly affects the taste and texture of the final products. From fluffy pastries to smooth chocolates, fine and uniform powdered sugar is the key to achieving premium quality. Traditional grinding methods often face challenges such as low efficiency, uneven particle size, easy caking, and thermal denaturation. However, in modern professional production lines, the powdered sugar mill – stainless steel toothed disc mill, with its targeted design, has become the core equipment for grinding high-quality powdered sugar, perfectly balancing efficiency and quality.

I. Precision Craftsmanship: An Analysis of Professional Milling Principles

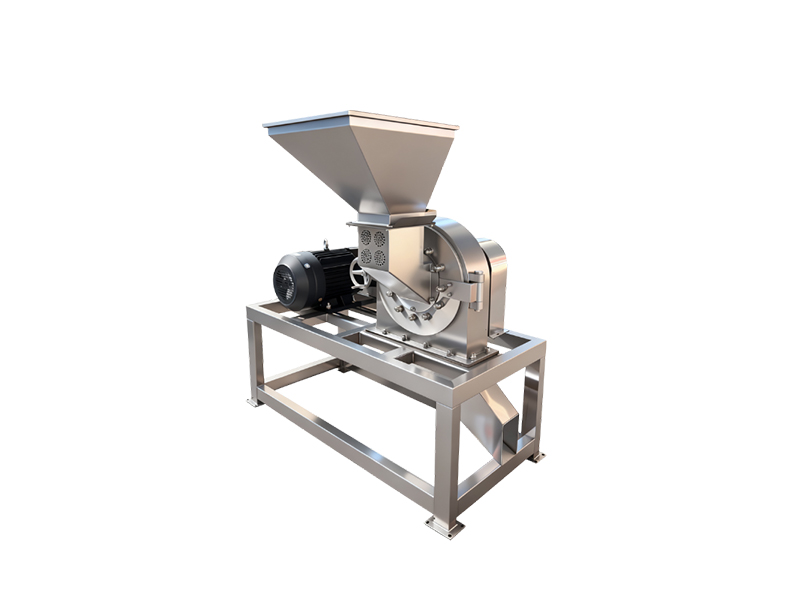

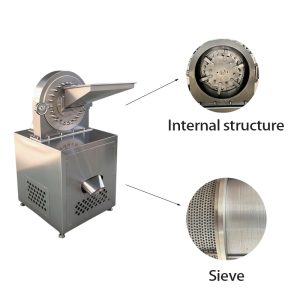

The grinding of sugar by the stainless steel toothed disc mill is an efficient and precise physical transformation. Its core lies in the precisely meshed gap formed between the high-speed rotating movable toothed disc and the stationary fixed toothed disc.

When dry crystalline granulated sugar is fed into the grinding chamber quantitatively, it is immediately subjected to the strong centrifugal force generated by the high-speed rotating toothed disc and thrown toward the sharp tooth grooves on the edge of the disc. In the tiny gaps where the movable and fixed teeth interlock, sugar particles are not simply “crushed” but mainly undergo intense shearing, collision, and friction. This multi-level composite force peels and refines the sugar crystals layer by layer from the inside out, forming extremely fine particles.

Particularly crucially, the equipment is usually integrated with a high-efficiency air-cooling and classification system. The airflow generated during grinding can not only timely take away the slight heat produced by friction, effectively preventing powdered sugar from melting or deteriorating due to temperature rise, but also quickly “extract” qualified fine powder from the grinding zone and deliver it to the cyclone separator for collection. On the other hand, unqualified coarse particles fall back to the grinding zone under the action of gravity or the classifier for secondary or even multiple grinding until the target fineness is achieved. This closed-circuit circulation grinding mode ensures a high degree of uniformity in the particle size of the finished product.

II. Distinct Advantages: Targeting the Pain Points of Powdered Sugar Production

Aiming at the characteristics of sugar as a special material, the stainless steel toothed disc mill demonstrates irreplaceable advantages:

- Excellent particle size control and powder output qualityBy precisely adjusting the disc gap, rotation speed, and classifier parameters, it can stably produce powdered sugar with different fineness ranging from 10 mesh to 120 mesh, with concentrated particle size distribution and good fluidity. The resulting powdered sugar has high fineness and pure color, retaining the original flavor and sweetness of granulated sugar to the greatest extent.

- High-efficiency anti-adhesion and anti-clogging, stable operationThe entire machine is made of food-grade 304 or 316 stainless steel with high surface finish, fundamentally eliminating rust contamination and preventing powdered sugar from adhering easily. The special toothed disc structure design, smooth inner cavity flow channel, and dust removal system effectively solve the problem of equipment clogging caused by moisture absorption and caking of powdered sugar, ensuring the stability of long-term continuous production.

- Low-temperature grinding, protecting the essence of raw materialsCombined with the air-cooling system and reasonable mechanical structure design, the temperature rise during grinding can be controlled within an extremely low range, perfectly adapting to the “heat sensitivity” of sugar. This avoids partial sugar melting, caramelization, or property changes caused by high temperatures, making it particularly suitable for processing high-end food raw materials sensitive to temperature.

- Durable and easy to cleanThe stainless steel material endows the equipment with excellent corrosion resistance and mechanical strength, ensuring long service life. The modular design enables the core grinding components to be quickly disassembled, cleaned, and maintained, complying with the strict hygiene standards of food production, and can easily meet the needs of switching production between different batches and varieties of materials.

The stainless steel powdered sugar mill is not only a simple grinding tool but also a precision processing system deeply optimized for the characteristics of sugar materials. It integrates high-efficiency production capacity, precise quality control, hygiene and safety, and stable operation, providing a reliable cornerstone for producing high-quality powdered sugar in food industry fields such as baking, confectionery, beverages, and instant products, and continuously helping to create a more delicate and delicious sweet experience.

Solutions pour le traitement des poudres - Pulvérisateurs, broyeurs et mélangeurs | Pcreate Machinery

Solutions pour le traitement des poudres - Pulvérisateurs, broyeurs et mélangeurs | Pcreate Machinery