Turmeric Powder Grinding Machine

349Achieve consistent superfine turmeric powder with our grinding machine. Engineered for precise particle control, smooth output, and reliable performance in food processing.

詳細を見る駅全体を検索

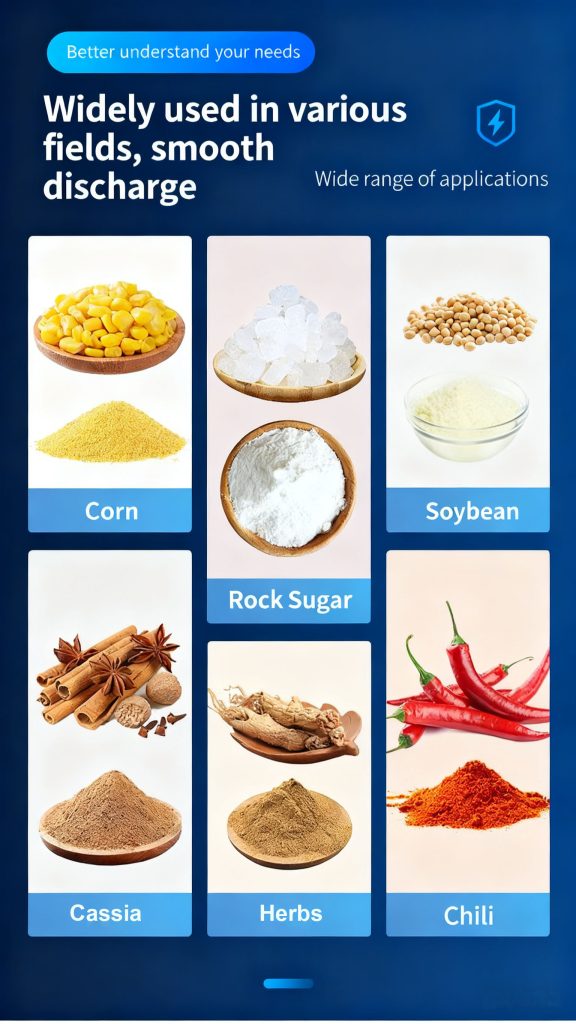

With global chili consumption exceeding 12 million tons, China, as a core producer and consumer, sees an annual consumption of over 8 million tons—growing at a steady 10% yearly. Traditional chili grinding equipment struggles with low efficiency, high energy consumption, and flavor loss. Our commercial chili grinder, boasting industrial-grade precision design, enables efficient conversion from raw materials to finished products. It not only ensures food safety but also maximizes the retention of chili’s natural aroma and nutrients, making it a core production equipment for chili product factories, restaurant chains, and condiment enterprises.

| モデル | Capacity (kg/h) | Grinding Fineness (mesh) | Main Motor Power (kW) | Overall Dimensions (mm) | Total Weight (kg) |

| 300 | 60-150 | 10-120 | 4 | 2750×1300×2850 | 265 |

| 400 | 200-400 | 10-120 | 7.5 | 3450×1300×2850 | 315 |

| 500 | 300-500 | 10-120 | 11 | 3500×1300×2850 | 408 |

| 600 | 400-600 | 10-120 | 15 | 3570×1300×2850 | 460 |

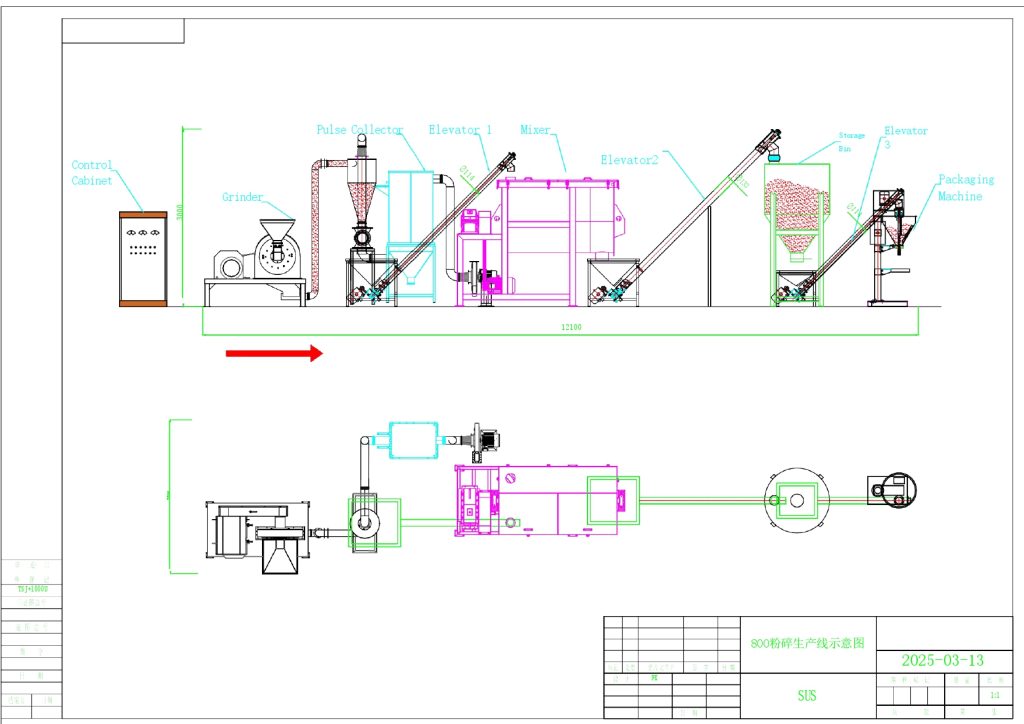

| 800 | 500-1000 | 10-120 | 22 | 3850×1300×2850 | 648 |

Achieve consistent superfine turmeric powder with our grinding machine. Engineered for precise particle control, smooth output, and reliable performance in food processing.

詳細を見るThe Shrimp skin Ultrafine Pulverizer is essentially a stainless steel toothed disc pulverizer. Its crushing fineness can be flexibly adjusted (10 to 120 meshes), which can accurately adapt to the production needs of food, feed, biological processi...

詳細を見るThe seaweed grinding machine is a high-efficiency powder processing equipment specifically designed for fibrous seaweed materials. It is suitable for grinding various dried seaweed raw materials such as kelp, nori, wakame, and spirulina. Addressin...

詳細を見るThe seaweed grinding machine is a high-efficiency powder processing equipment specifically designed for fibrous seaweed materials. It is suitable for grinding various dried seaweed raw materials such as kelp, nori, wakame, and spirulina. Addressin...

詳細を見るこのウェブサイトでは、お客様の閲覧体験を向上させるためにクッキーを使用しています。本サイトの利用を継続することにより、クッキーの使用に同意したものとみなされます。このウェブサイトから収集されたデータは、米国で処理・保存されます。