駅全体を検索

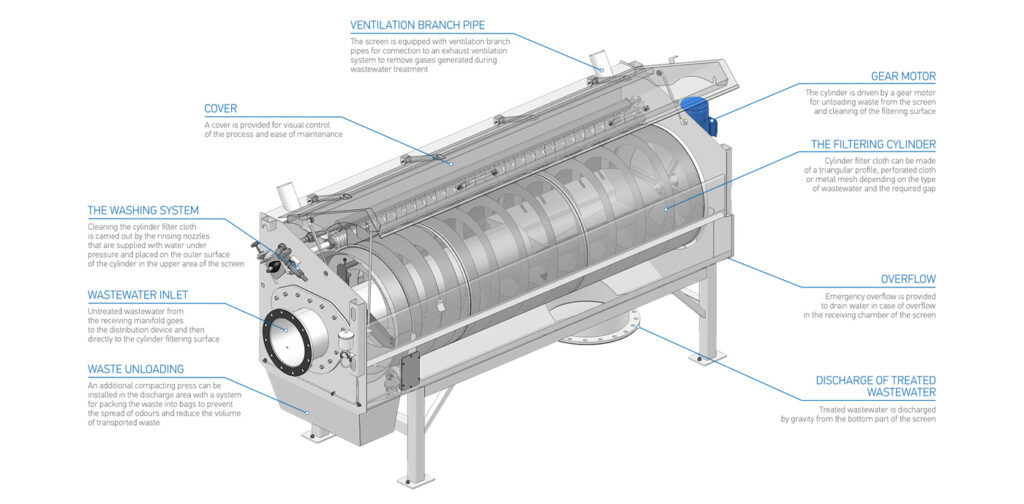

A ロータリードラムスクリーン is a mechanical filtration device designed for solid-liquid separation, commonly used in wastewater treatment, food processing, chemical production, and various industrial processes.

It efficiently removes suspended solids, fibers, and particles from liquids through a continuously rotating drum fitted with a fine mesh or perforated plate.

The drum screen provides stable, automatic filtration, low maintenance, and 連続運転, making it ideal for high-capacity production lines.

一般的な生産工程では

Raw Material → Washing / Separation → ロータリードラムスクリーン → Filtrate → Next Processing Step

The rotary drum screen acts as a pre-treatment or separation station による:

Removes suspended solids, fibrous materials, and residues from liquids with high precision.

The rotating drum allows 24/7 filtration with self-cleaning function, minimizing downtime.

Designed with quick-access covers and modular parts for easy cleaning and inspection.

Ensures consistent particle removal and stable flow rate throughout the process.

Low power consumption and high throughput make it suitable for large-scale industrial applications.

| 構造タイプ | Drum Material | Mesh Type | Cleaning Method |

|---|---|---|---|

| Open Drum Type | SS304 / SS316L | Wedge Wire | Backwash Spray |

| Enclosed Type | SS316L | Perforated Plate | Brush + Rinse |

| Inclined Type | 炭素鋼 | Wire Mesh | Rotary Cleaning System |

| モデル | Drum Diameter (mm) | Length (mm) | Mesh Size (mm) | 素材 | Capacity (m³/h) | Application |

|---|---|---|---|---|---|---|

| RDS-600 | 600 | 1000 | 0.3 | SS304 | 5–15 | Food, Beverages |

| RDS-800 | 800 | 1200 | 0.5 | SS304 | 10–25 | Wastewater |

| RDS-1000 | 1000 | 1500 | 1.0 | SS316L | 20–40 | ケミカル |

| RDS-1200 | 1200 | 2000 | 2.0 | SS316L | 30–60 | Pulp, Paper |

As a crucial solid-liquid separation device, the ロータリードラムスクリーン ensures smooth and efficient operation of industrial production lines.

It improves product quality, reduces maintenance costs, and enhances automation levels across multiple industries.

Whether for food, wastewater, or chemical applications, it stands as a reliable and energy-efficient solution for continuous filtration and solid removal.

このウェブサイトでは、お客様の閲覧体験を向上させるためにクッキーを使用しています。本サイトの利用を継続することにより、クッキーの使用に同意したものとみなされます。このウェブサイトから収集されたデータは、米国で処理・保存されます。