전체 방송국 검색

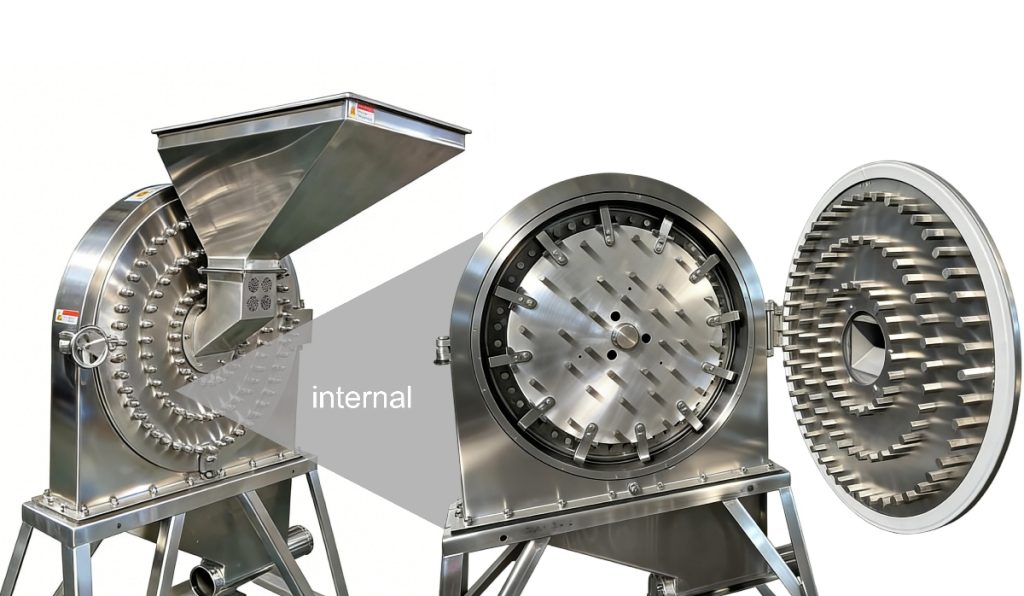

A pin mill is a type of industrial grinding machine that uses high-speed rotating discs fitted with rows of intermeshing pins to reduce materials into fine powders through repeated impact and shearing

It works by using two discs fitted with multiple pins—one rotating at high speed and the other stationary or counter-rotating. When material enters the grinding chamber, it is broken down by impact and shear forces generated between the pins.

Pin mills are widely used because they offer:Uniform particle size;High grinding efficiency;Low heat generation;Continuous operation

They are commonly applied in the food, pharmaceutical, chemical, and mineral industries, especially for materials such as spices, sugar, salt, chemicals, and powders that require precise fineness control.

A stainless steel pin mill with a pulse dust collector is a production-scale grinding system that combines a hygienic grinding chamber and an on-board filtration unit. The pin mill reduces bulk solids into fine powder; the pulse dust collector captures airborne fines and automatically cleans its filter media with short bursts (“pulses”) of compressed air. The result is controlled dust emission, stable output and easier compliance with food/pharma hygiene standards.

스테인리스 스틸(일반적으로 304 또는 316L)은 몇 가지 실용적인 이유로 선택됩니다:

The output fineness of our pin mills is primarily and precisely controlled by replacing screen meshes with different aperture sizes. The screen is installed at the outlet of the grinding chamber, allowing only particles smaller than the mesh openings to pass through. We offer a range of screens from 10 mesh to 120 mesh (and finer), enabling customers to easily switch between screens based on the particle size requirements of their final product. This simple and reliable mechanical sieving method ensures stable and controllable adjustment of output fineness.

1. Standalone pin mill (stainless steel body)

추가 옵션: 제어식 피더가 있는 피드 호퍼, 분쇄 후 진동 체, 샘플 포트, 식품/제약 애플리케이션을 위한 풀 스테인리스 덕트.

| 모델 | 크기(mm) | 전원 | 전압 | 무게(kg) | 크러싱 미세도(메시) | 처리량(kg/h) |

|---|---|---|---|---|---|---|

| 200 | 4060 × 800 × 2750 | 2.2kW | 220V | 471 | 10 – 120 | 30 – 50 |

| 300 | 4160 × 800 × 2750 | 4kW | 380V | 515 | 10 – 120 | 60 – 150 |

| 400 | 4850 × 930 × 2750 | 7.5 kW | 380V | 565 | 10 – 120 | 200 – 400 |

| 500 | 4900 × 1000 × 2750 | 11 kW | 380V | 658 | 10 – 120 | 300 – 500 |

| 600 | 5000 × 990 × 2750 | 15kW | 380V | 710 | 10 – 120 | 400 – 600 |

| 800 | 5380 × 1150 × 2930 | 22kW | 380V | 898 | 10 – 120 | 500 – 1000 |

| 1000 | 5500 × 1170 × 3160 | 30kW | 380V | 1200 | 10 – 120 | 800 – 1200 |

How to solve overheating in a pin mill? Which cooling solution is better?

To address grinding temperature rise, we offer both rear-mounted high-power fans and water-cooling systems, with a strong recommendation for the former. The key advantage lies in the dual function of our rear fan:

1) Efficient Cooling: The airflow directly removes frictional heat from the grinding chamber, providing significant and uniform temperature reduction.

2) Smooth Discharge: The airflow actively propels and conveys the ground material out of the chamber, effectively preventing fine powder from lingering or clogging.

This integrated “cooling + conveying” design is superior to passive water-cooling in preserving the material’s original color and aroma, while also offering a simpler and maintenance-free setup.

이 웹사이트는 사용자의 브라우징 경험을 개선하기 위해 쿠키를 사용합니다. 이 사이트를 계속 이용하면 쿠키 사용에 동의하는 것으로 간주됩니다. 이 웹사이트에서 수집된 데이터는 미국에서 처리 및 저장됩니다.