전체 방송국 검색

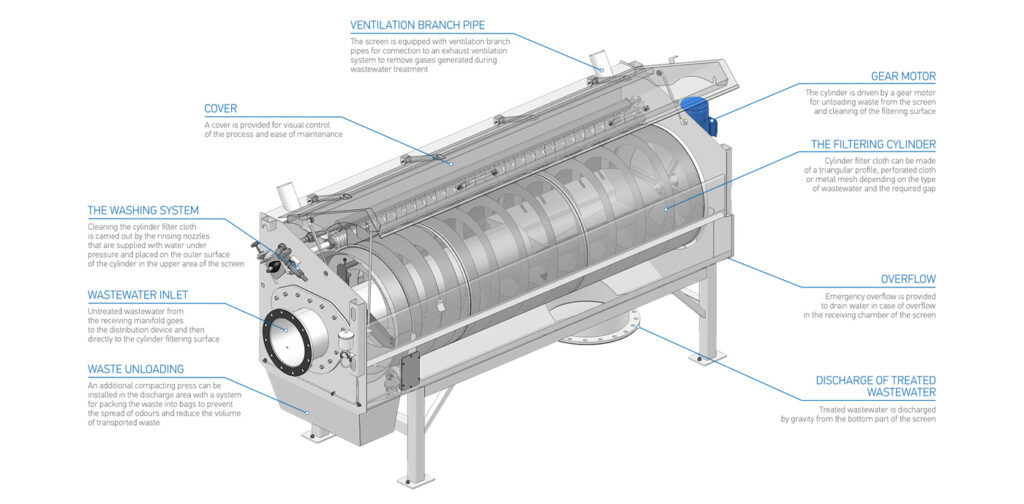

A rotary drum screen is a mechanical filtration device designed for solid-liquid separation, commonly used in wastewater treatment, food processing, chemical production, and various industrial processes.

It efficiently removes suspended solids, fibers, and particles from liquids through a continuously rotating drum fitted with a fine mesh or perforated plate.

The drum screen provides stable, automatic filtration, low maintenance, and 연속 작동, making it ideal for high-capacity production lines.

In a typical production process:

Raw Material → Washing / Separation → 로터리 드럼 화면 → Filtrate → Next Processing Step

The rotary drum screen acts as a pre-treatment or separation station by:

Removes suspended solids, fibrous materials, and residues from liquids with high precision.

The rotating drum allows 24/7 filtration with self-cleaning function, minimizing downtime.

Designed with quick-access covers and modular parts for easy cleaning and inspection.

Ensures consistent particle removal and stable flow rate throughout the process.

Low power consumption and high throughput make it suitable for large-scale industrial applications.

| Structure Type | Drum Material | Mesh Type | Cleaning Method |

|---|---|---|---|

| Open Drum Type | SS304 / SS316L | Wedge Wire | Backwash Spray |

| Enclosed Type | SS316L | Perforated Plate | Brush + Rinse |

| Inclined Type | Carbon Steel | Wire Mesh | Rotary Cleaning System |

| 모델 | Drum Diameter (mm) | Length (mm) | Mesh Size (mm) | Material | Capacity (m³/h) | Application |

|---|---|---|---|---|---|---|

| RDS-600 | 600 | 1000 | 0.3 | SS304 | 5–15 | Food, Beverages |

| RDS-800 | 800 | 1200 | 0.5 | SS304 | 10–25 | Wastewater |

| RDS-1000 | 1000 | 1500 | 1.0 | SS316L | 20–40 | Chemical |

| RDS-1200 | 1200 | 2000 | 2.0 | SS316L | 30–60 | Pulp, Paper |

As a crucial solid-liquid separation device, the 로터리 드럼 화면 ensures smooth and efficient operation of industrial production lines.

It improves product quality, reduces maintenance costs, and enhances automation levels across multiple industries.

Whether for food, wastewater, or chemical applications, it stands as a reliable and energy-efficient solution for continuous filtration and solid removal.

이 웹사이트는 사용자의 브라우징 경험을 개선하기 위해 쿠키를 사용합니다. 이 사이트를 계속 이용하면 쿠키 사용에 동의하는 것으로 간주됩니다. 이 웹사이트에서 수집된 데이터는 미국에서 처리 및 저장됩니다.