Sugar Grinder Complete Guide: Principles, Usage, Selection & Applications

1501The sugar grinder is used in the production and processing of biscuits, cakes, coffee, milk powder, jams, potato chips and other products.

အသေးစိတ်ကြည့်ရှုပါ။ဘူတာရုံတစ်ခုလုံးကို ရှာဖွေပါ။

For herbal, grain and dietary supplement powder processors worldwide, choosing the wrong nutrition powder machine is more than a bad purchase—it means production halts, raw material waste, or a mismatch between the equipment’s voltage and your local workshop.

Far too many buyers focus excessively on price while ignoring core specs like raw material adaptability နှင့် industrial-grade construction, only to end up needing costly replacements for the powder machine within months.

Pcreate Machinery’s nutrition powder machine buying guide cuts through the noise, offering practical, step-by-step advice to precisely match industrial-grade equipment to your production capacity, raw material type and target market—no guesswork, no avoidable pitfalls.

When grinding herbal raw materials like moringa and ganoderma into nutritional powder, choosing the right nutrition powder machine requires close attention to these key factors:

တစ် tooth disc mill with low-temperature cooling + food-grade stainless steel + adjustable tooth disc gap is the top choice. Pcreate Machinery’s water-cooled tooth disc mill is the perfect match, capable of grinding herbal raw materials directly into finished nutritional powder.

Tailored for herbal raw materials, this nutrition powder machine addresses all the key selection criteria above with outstanding performance:

The nutrition powder machine combines precise low-temperature control (cavity temp < 50℃), ultra-fine grinding (80–120 mesh) နှင့် anti-stick design—perfectly suited for the tender, slightly oily nature of moringa. It prevents volatile oil loss from high temperatures and powder clumping caused by oil content.

Pcreate’s nutrition powder machine crushes materials via high-speed meshing of moving and stationary tooth discs, generating shearing and impact forces for efficient grinding.

| Aspect | Specification & Benefit |

| Temperature Control | Cavity temperature rise ≤50℃: Prevents nutrient loss in herbal raw materials during grinding |

| Fineness Adjustment | 80–120 mesh: Produces fine, uniformly textured powder |

| Material Adaptability | Negative pressure discharge + cyclone separation; anti-stick cavity: No clumping or dust leakage |

| Sanitation Standard | 304/316 stainless steel in material contact areas + quick-release structure: Food-grade, no residue, easy to clean |

Pcreate Machinery – Nutrition Powder Machine (600 Series)

| Parameter | Specification |

| မော်ဒယ် | 600 Series (with dust removal device at the rear) |

| Material | 304/316 stainless steel |

| Overall Dimension | 4900×1200×2600mm |

| Screen Ring Diameter | 510mm |

| Feed Inlet Size | 130×150mm |

| Feed Hopper Size | 450×370mm |

| Feed Inlet Height (from ground) | 1360mm |

| Main Shaft Speed | 3200r/min |

| Output Capacity | 300–1200kg/h (varies by raw material and grinding fineness) |

| Grinding Fineness | 10–120 mesh |

| Net Weight | Approx. 420kg |

| ဓာတ်အား | 380V |

| မော်တော်ပါဝါ | 15kW |

| Auxiliary Functions | Dust removal + water cooling |

| Temperature Control Capability | ≤60℃ |

| Cleaning Design | Quick-release structure (fully detachable for cleaning) |

When grinding grains, plant extracts, or dried fruits/vegetables into nutritional powder, picking the right nutrition powder machine boils down to matching its specs to your raw material’s unique quirks. Here’s the lowdown on what to look for—plus our top Pcreate recommendations for each category:

Grains are tough and dense, so your nutrition powder machine needs serious power and staying power:

Extracts (especially spray-dried powders) love absorbing moisture, clumping up, and getting ruined by heat—so focus on:

Even dried, these have tough fibers—you need sharp, fast cutting power:

This nutrition powder machine is built for grain’s toughness—no frills, just reliable grinding:

| Parameter | Specification |

| မော်ဒယ် | 400 Series All-Enclosed Standalone |

| Material | 201/304/316 stainless steel |

| Overall Dimension | 640×1010×1170mm |

| Screen Ring Diameter | 360mm |

| Main Shaft Speed | 4500r/min |

| Output Capacity | 100–500kg/h (varies by raw material and grinding fineness) |

| Net Weight | Approx. 159kg |

| ဓာတ်အား | 380V |

| မော်တော်ပါဝါ | 7.5kW |

| Grinding Fineness | 10–120 mesh |

Ticks all the boxes for moisture-prone, heat-sensitive extracts:

| Parameter | Specification |

| မော်ဒယ် | 400 Series with Dust Removal Device |

| Material | 201/304/316 stainless steel |

| Overall Dimension | 3450×1300×2850mm |

| Screen Ring Diameter | 370mm |

| Main Shaft Speed | 4500r/min |

| Output Capacity | 100–500kg/h (varies by raw material and grinding fineness) |

| Net Weight | Approx. 176kg |

| ဓာတ်အား | 380V |

| မော်တော်ပါဝါ | 7.5kW |

| Grinding Fineness | 10–120 mesh |

| Auxiliary Functions | Dust removal + water cooling |

| Temperature Control Capability | ≤60℃ |

| Cleaning Design | Quick-release structure (fully detachable for cleaning) |

Fast, sharp, and sized for different production scales—perfect for tough dried produce:

| Parameter | 300 Series | 400 Series |

| မော်ဒယ် | 300 Series | 400 Series |

| Material | 201/304/316 stainless steel | 201/304/316 stainless steel |

| Overall Dimension | 910×830×1100mm | 1180×840×1260mm |

| Main Shaft Speed | 5700r/min | 4500r/min |

| Output Capacity | 60–150kg/h | 200–400kg/h |

| Net Weight | 147kg | 197kg |

| ဓာတ်အား | 220V/380V | 220V/380V |

| မော်တော်ပါဝါ | 4kW | 7.5kW |

| Grinding Fineness | 10–120 mesh | 10–120 mesh |

Picking the right nutrition powder machine gear all comes down to matching your hourly output target—whether you’re running a small startup batch line or a full-scale commercial plant. Below are our tailored Pcreate nutrition powder machine recommendations for 50kg/h, 300kg/h, and 800kg/h+ production, plus a complete turnkey production line for large-scale manufacturing needs.

Perfect for small-batch production, home-based workshops, or test runs—compact, energy-efficient, and easy to operate with flexible voltage options.

| Parameter | Specification |

| မော်ဒယ် | 300 Series Nutrition Powder Machine |

| Material | 201/304/316 stainless steel |

| Overall Dimension | 910×830×1100mm |

| Main Shaft Speed | 5700r/min |

| Output Capacity | 60–150kg/h (varies by raw material and grinding fineness) |

| Net Weight | Approx. 147kg |

| ဓာတ်အား | 220V/380V |

| မော်တော်ပါဝါ | 4kW |

| Grinding Fineness | 10–120 mesh |

Ideal for steady commercial batch production—adds dust control and low-temperature grinding for heat-sensitive materials, with a wider output range to meet growing demand.

| Parameter | Specification |

| မော်ဒယ် | 400 Series with Dust Removal Device |

| Material | 201/304/316 stainless steel |

| Overall Dimension | 3450×1300×2850mm |

| Screen Ring Diameter | 370mm |

| Main Shaft Speed | 4500r/min |

| Output Capacity | 100–500kg/h (varies by raw material and grinding fineness) |

| Net Weight | Approx. 176kg |

| ဓာတ်အား | 380V |

| မော်တော်ပါဝါ | 7.5kW |

| Grinding Fineness | 10–120 mesh |

| Auxiliary Functions | Dust removal + water cooling |

| Temperature Control Capability | ≤60℃ |

| Cleaning Design | Quick-release structure (fully detachable for cleaning) |

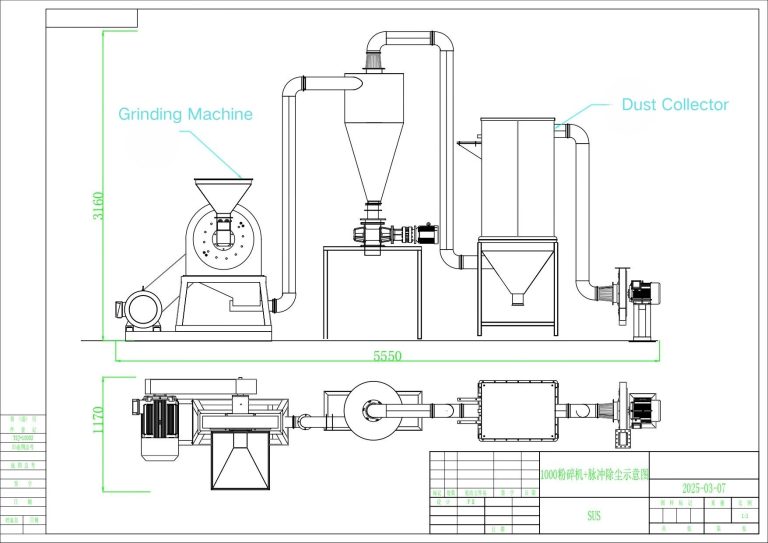

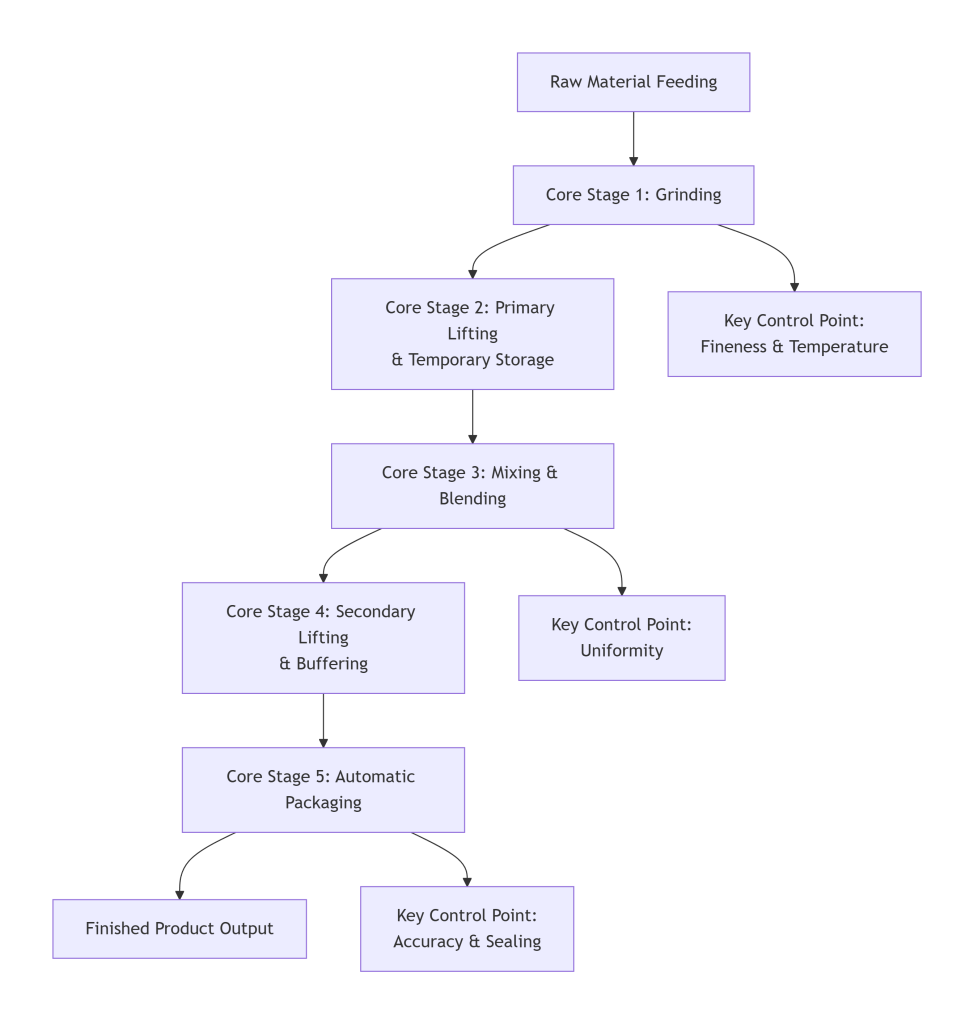

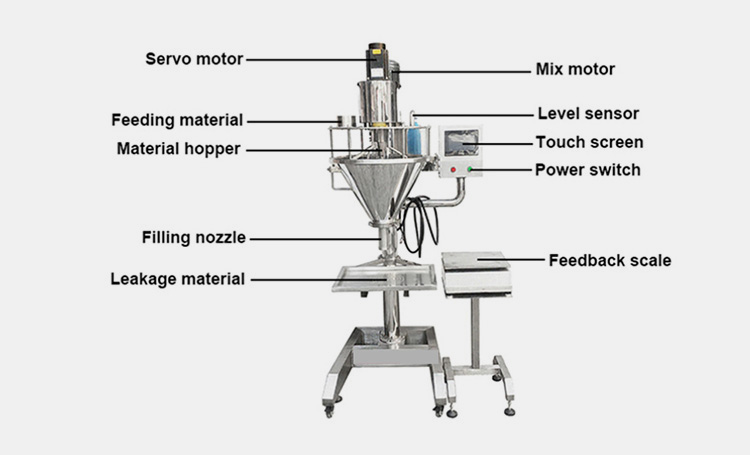

If you’re a large-scale processor needing 1 ton/h+ output, our fully automated production line is the ultimate solution. It integrates grinding, conveying, mixing, and packaging into a seamless closed-loop system—designed for continuous 24/7 operation, minimal labor, and consistent product quality. It works for herbs, grains, dried fruits/veggies, plant extracts, and even food seasonings like coffee beans, chili powder, and sugar powder.

Each stage is engineered to sync with the next for smooth, high-efficiency production—here’s the breakdown of every key step, plus what to look for when selecting equipment:

The make-or-break first step that defines your powder’s baseline quality.

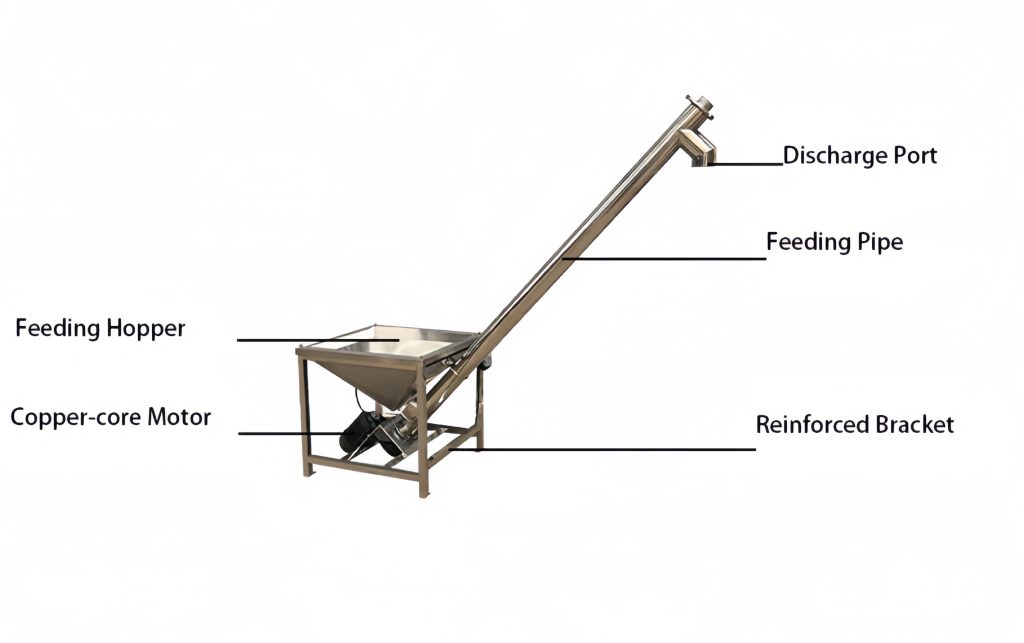

Conveys ground powder to the top of the mixer—no manual lifting, no mess.

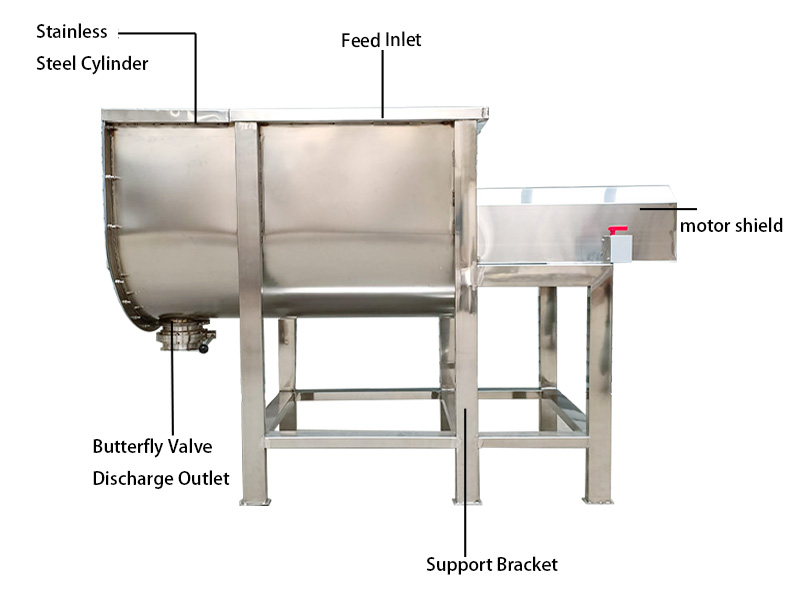

The heart of consistent powder quality—ensures every scoop has the same ingredient ratio.

Feeds blended finished powder to the packaging machine’s hopper—acts as a buffer for steady packaging.

The final step that impacts your product’s shelf life and visual appeal.

When building a large-scale nutrition powder line, individual equipment specs aren’t enough—the whole system needs to work as one. These four principles are non-negotiable for a smooth, efficient, and compliant line:

The key to choosing a nutrition powder machine mill isn’t slashing upfront costs—it’s about an exact match for your actual production needs. Voltage compatibility, raw material suitability, and machine construction are the core factors that keep your production line running steadily and reliably.

Stick to the step-by-step approach in Pcreate Machinery’s nutrition powder machine mill buying guide, and you’ll find the perfect equipment that aligns with your production capacity. This means zero unplanned downtime, less raw material waste, and no costly machine replacements caused by ill-fitting gear—all for your herbal, grain, and dietary supplement powder production.

Absolutely. You must ensure raw materials are completely dry prior to grinding—this prevents clumping, mold growth, and machine clogs during the grinding process.

You can adjust the powder fineness easily by swapping out the screen mesh with different pore sizes.

Definitely! This mill isn’t just designed for herbs, grains, dried fruits & vegetables, and plant extracts—it also works perfectly for grinding spices and various food ingredients, such as coffee beans, cocoa beans, dried banana slices, and white granulated sugar.

Pcreate Machinery specializes in complete sets of equipment for the powder processing industry, covering the entire production chain from single-unit machines to integrated systems—including crushing, conveying, mixing, screening, and granulation. Our products serve a wide range of sectors, such as food additives, baking ingredients, pharmaceutical intermediates, health food, and chemical raw materials.

Backed by advanced technologies, sophisticated craftsmanship, and a comprehensive pre-sales service system, we have earned consistent praise from customers both at home and abroad. We prioritize establishing long-term partnerships with clients, and have witnessed the growth of numerous customers through our top-tier product quality နှင့် dedicated service.

We firmly believe that quality and efficiency are reflected in every detail—from engineering design, R&D experiments, to equipment manufacturing, installation, and commissioning. We strive to optimize every step to ensure our machines perform at their peak.

The sugar grinder is used in the production and processing of biscuits, cakes, coffee, milk powder, jams, potato chips and other products.

အသေးစိတ်ကြည့်ရှုပါ။The stainless steel powdered sugar mill is not only a simple grinding tool but also a precision processing system deeply optimized for the characteristics of sugar materials. It integrates high-efficiency production capacity, precise quality cont...

အသေးစိတ်ကြည့်ရှုပါ။Our ultra fine grinder delivers uniform, ultra-fine powder for spice, herb, food and chemical industries. Customizable for your material.

အသေးစိတ်ကြည့်ရှုပါ။All herb-contacting parts are made of 304 stainless steel, which is safe, non-toxic, and corrosion-resistant, The sealed dust-proof design prevents powder from flying during mixing。

အသေးစိတ်ကြည့်ရှုပါ။ဤဝဘ်ဆိုက်သည် သင်၏ရှာဖွေမှုအတွေ့အကြုံကို မြှင့်တင်ရန် ကွတ်ကီးများကို အသုံးပြုသည်။ ဤဆိုက်ကို ဆက်လက်အသုံးပြုခြင်းဖြင့်၊ ကျွန်ုပ်တို့၏ cookies များကို သင်လက်ခံပါသည်။ ဤဝဘ်ဆိုက်မှ စုဆောင်းရရှိသော အချက်အလက်များကို အမေရိကန်ပြည်ထောင်စုတွင် စီမံဆောင်ရွက်ပြီး သိမ်းဆည်းထားသည်။