Tìm kiếm toàn bộ nhà ga

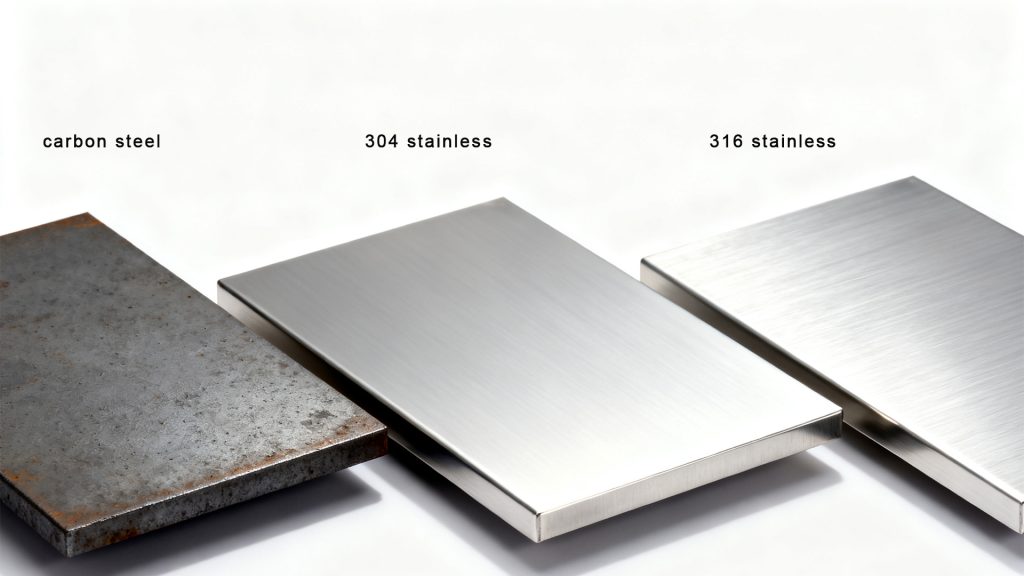

A storage silo is an auxiliary device designed for temporary storage and buffering of bulk materials, commonly used in powder and granule production lines. It is usually made of carbon steel or stainless steel, providing stable storage, controlled discharging, and seamless connection to the next process.

In a typical production process:

Grinding → Mixing → Elevating → Silo → Elevating → Packaging.

The silo serves as a buffering station by:

| Người mẫu | Capacity (m³) | Material | Discharge Type | Applications |

| Silo-2 | 2 | SS304 | Vít tải | Food, Pharma |

| Silo-5 | 5 | Carbon Steel | Pneumatic Gate | Chemicals, Feed |

| Silo-10 | 10 | SS316L | Vibrating Discharge | Spices, Additives |

| Silo-20 | 20 | Carbon Steel | Screw + Gate Combined | Building Materials |

As an auxiliary device in production lines, a silo not only provides buffering and transition but also enhances continuity and automation. It has become an essential part of powder and granule processing systems.

Trang web này sử dụng cookie để cải thiện trải nghiệm duyệt web của bạn. Bằng việc tiếp tục sử dụng trang web này, bạn chấp nhận việc sử dụng cookie của chúng tôi. Dữ liệu thu thập từ trang web này được xử lý và lưu trữ tại Hoa Kỳ.