Search the whole station

Capacity: 100–2000 kg/h

Advantages: High Production Capacity | Versatile Output Sizes | Diverse Applications

Suitable for long-term projects with varying locations and durations.

Applications and Advantages:

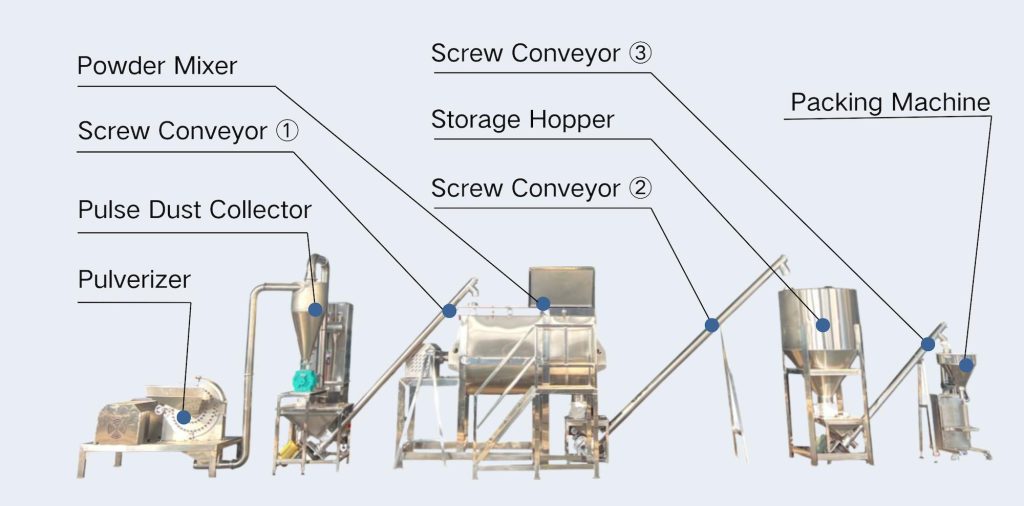

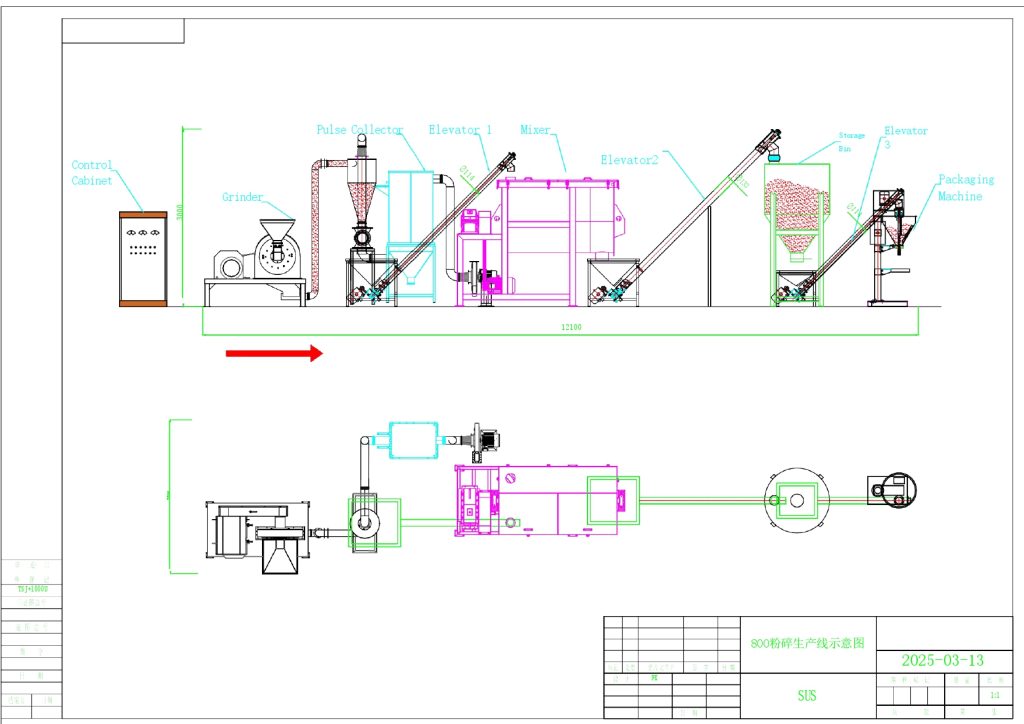

This production line is designed for grinding and blending calcium carbonate into fine, uniform powder suitable for plastics, paints, coatings, paper, and other industrial applications. The disc mill ensures consistent particle size, improving dispersibility and surface smoothness. Integrated drum mixing guarantees homogeneous blending with additives or other mineral powders. The vibrating sieve removes oversized particles, ensuring high-quality output. Dust collection systems maintain a clean and safe working environment, meeting industrial hygiene standards. Durable construction and easy maintenance make it ideal for continuous production in chemical and mineral powder industries.

Our systems cover a wide range of capacities, from 100 kg/h up to 5000 kg/h, depending on the material and production requirements.

Absolutely. We offer full processing lines including feeding, grinding, mixing, conveying, dust collection, and packaging—tailored to your project needs.

Yes, our equipment handles spices, grains, herbs, and even minerals, with solutions customized to your needs.

All machines are built with durable construction, designed for stable performance, long service life, and easy maintenance, ensuring reliable operation in long-term projects.

Pcreate Machinery provides advanced feed processing solutions, including powder and pellet equipment, ensuring uniform nutrition, high efficiency, and consistent quality for animal feed production.

Tailored food processing solutions including powder grinding, mixing, and packaging, ensuring hygiene, consistent quality, and operational efficiency for food manufacturers.

Complete mineral processing solutions for efficient grinding, powder production, and particle uniformity, enabling high-quality output for chemical, construction, and industrial applications.

Advanced pharmaceutical processing solutions for powder and granule production, blending, and handling, ensuring compliance, quality, and efficiency in drug manufacturing.

Efficient spice processing solutions for grinding, blending, and packaging, preserving aroma and quality, and supporting commercial spice production across the food industry.

loading…

已经是到最后一篇内容了!

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.