Lini Produksi Penghancuran Rempah-rempah

1090Lini penghancuran rempah-rempah lengkap untuk pemrosesan dengan efisiensi tinggi, ukuran partikel yang seragam, dan produksi yang dioptimalkan dalam industri makanan dan bumbu.

Lihat detailCari seluruh stasiun

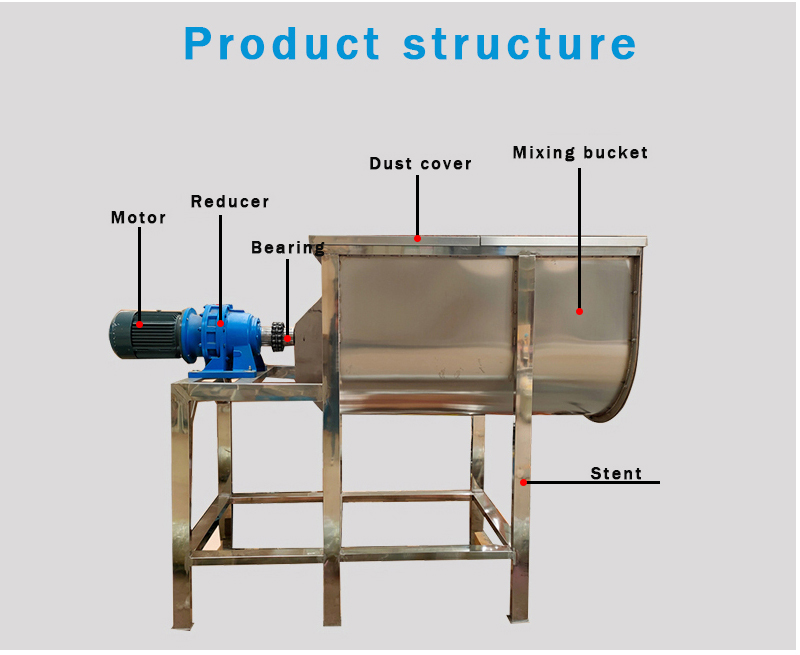

The ribbon type dry powder mixer can also be referred to as a stainless steel U-type dry powder mixer. It is called a ribbon mixer because its mixing blades are ribbon-shaped. This ribbon mixer is primarily used for mixing dry powder materials. Whether it’s food powder, pharmaceutical powder, or chemical powder, it can mix them uniformly with high output and short mixing time. The mixer is mainly made of 201 stainless steel, 304 stainless steel, or 316 stainless steel. The choice of material depends on the specific raw materials being processed.

The ribbon type dry powder mixer quickly blends materials. Under the movement of the spiral ribbon on the mixing shaft, the inner and outer spiral ribbons tumble the materials over a large range. The inner spiral ribbon moves materials towards both sides, while the outer spiral ribbon moves materials from both sides inward, causing the materials to mix back and forth. Additionally, part of the material is pushed by the spiral ribbon to move axially and radially, thus forming a convective cycle. Due to the mixing action described above, the materials achieve rapid and uniform mixing in a short time. The homogenization mixing time per batch is approximately 5-15 minutes. For multiple materials with significant differences in proportion or properties, the mixing time should be determined based on actual results.

Advantages of the Ribbon Type Dry Powder Mixer:Adopts a U-shaped barrel structure, ensuring stable operation, uniform mixing, no dead angles, clean discharge, and a wide range of applications.Utilizes interlocking inner and outer double-layer ribbons for reciprocating mixing, resulting in fast mixing speed and high uniformity.Bearings are located at both ends of the mixer, making it difficult for material to enter, leading to low maintenance rates.

Equipped with national standard pure copper motors, providing strong power and effective mixing performance.

Uses R-series reducers, which are quiet, environmentally friendly, and have a long service life.

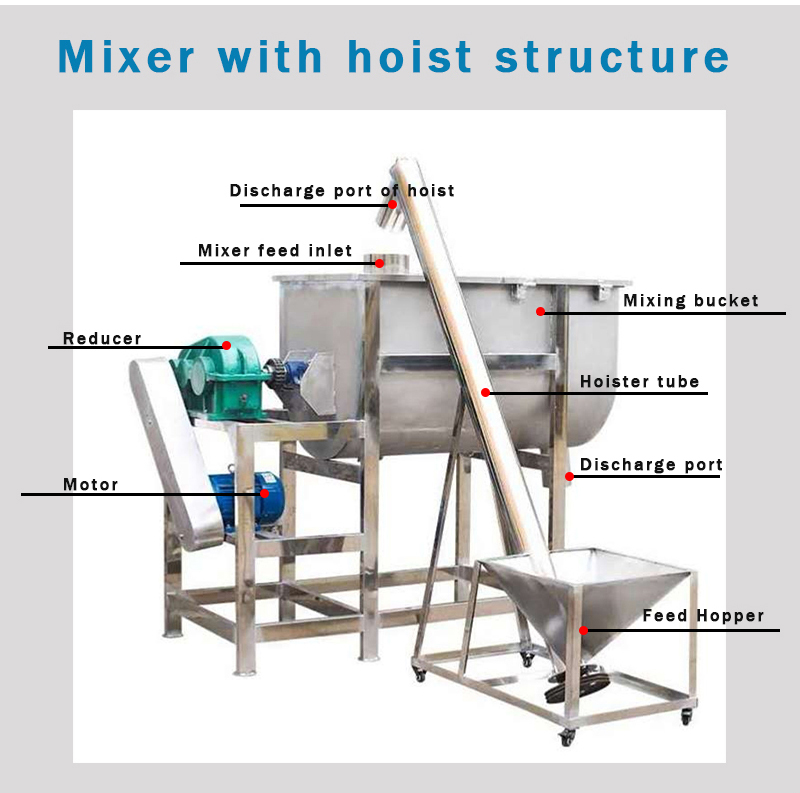

Can be fed using a stainless steel Konveyor Sekrup for convenient loading. The feed inlet is level with the ground, making feeding labor-saving and easy.

Scrapers are added to the mixing blades for clean discharge with no residue.

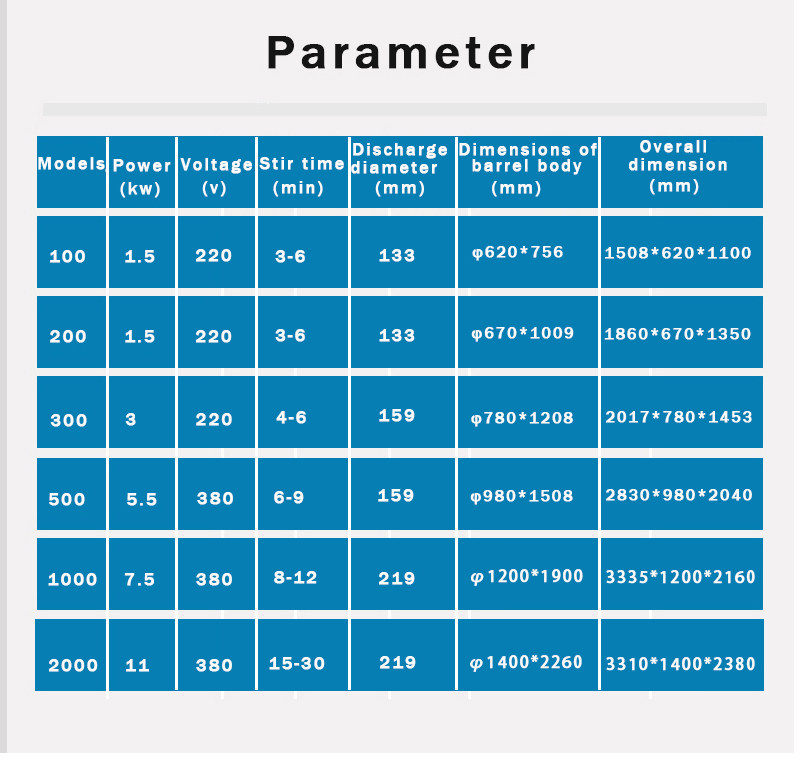

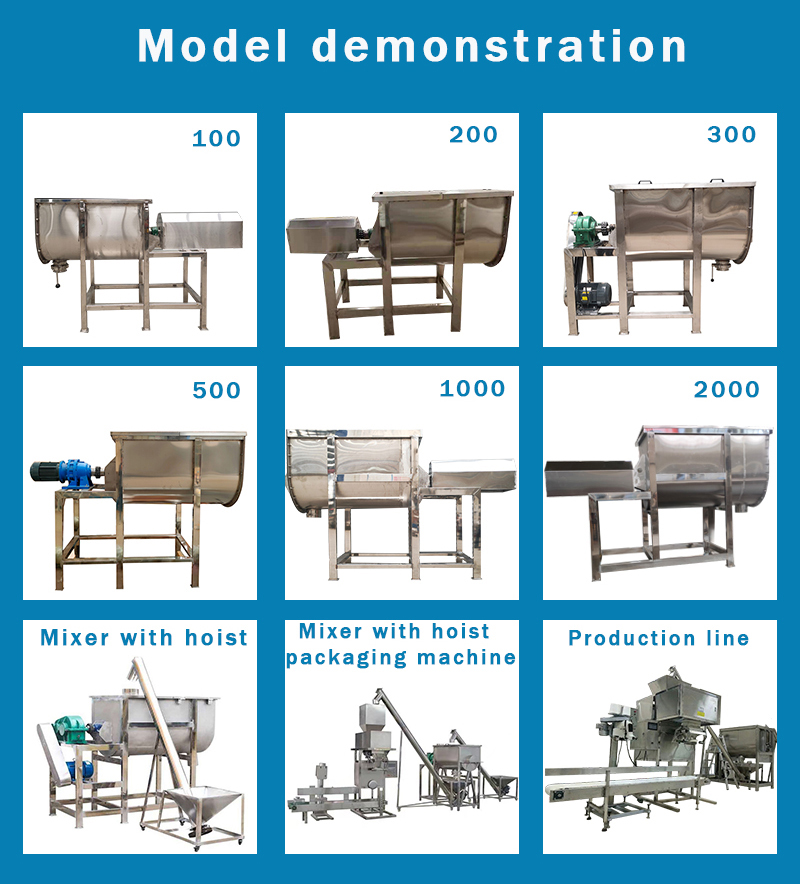

The ribbon type dry powder mixer comes in many models: 100, 200, 300, 500, 1000, 2000, 3000 , and custom options are available. Various feeding and discharging methods can be selected. Feeding options include screw feeders and vacuum powder suckers. Discharging options include manual gate valves, manual butterfly valves, manual flap valves, pneumatic gate valves, pneumatic valves, and pneumatic flap valves. The ribbon type dry powder mixer can be equipped with dry powder humidification spray and misting functions (the atomization state varies depending on the viscosity of the liquid, appearing as a spray, leading to shorter material uniformization time, higher uniformity, and increased production capacity).

The Ribbon Type Dry Powder Mixer Can Be Used For MixingFood powders, flour, starch, corn flour, wheat flour, bread crumbs, white sugar, salt, cocoa powder, coffee powder, milk tea powder, food additives, seasoning powder, chili powder, pepper powder, star anise powder, cumin powder, spice powders, curry powder, solid beverage granules, glucose powder, soybean powder, bread flour,Dry-mix mortar, iron yellow, iron black, iron red, carbon black, pigments, titanium dioxide, calcium carbonate, bentonite, diatomaceous earth, food preservatives, water reducers, kaolin, resin, cement, fly ash, lime powder, calcium carbonate, talcum powder, gypsum powder, kaolin, gypsum powder, talcum powder, hydrated lime powder, heavy calcium carbonate, calcium oxide, coal powder, stone powder, carbon black, alumina, fireproof materials, and other powders.

Lini penghancuran rempah-rempah lengkap untuk pemrosesan dengan efisiensi tinggi, ukuran partikel yang seragam, dan produksi yang dioptimalkan dalam industri makanan dan bumbu.

Lihat detailPenggiling biji kakao yang cocok untuk pemrosesan cokelat, makanan, dan minuman, menawarkan efisiensi tinggi, ukuran partikel yang seragam, dan dukungan lini produksi.

Lihat detailPenghancur garam baja tahan karat untuk menggiling garam dan mineral dengan efisiensi tinggi, memastikan ukuran partikel yang seragam untuk industri makanan dan kimia.

Lihat detailPenggiling lada untuk pemrosesan rempah-rempah yang tepat dan efisien, memastikan ukuran partikel yang seragam dan produksi yang dioptimalkan dalam lini makanan dan bumbu.

Lihat detailSitus web ini menggunakan cookie untuk meningkatkan pengalaman menjelajah Anda. Dengan terus menggunakan situs ini, Anda menerima penggunaan cookie kami. Data yang dikumpulkan dari situs web ini diproses dan disimpan di Amerika Serikat.