Onion Powder Making Machine

1449ချောကလက်၊ အစားအစာနှင့် အဖျော်ယမကာ ပြုပြင်ခြင်းအတွက် သင့်လျော်သော ကိုကိုးစေ့ကြိတ်စက်သည် မြင့်မားသော ထိရောက်မှု၊ တူညီသော အမှုန်အမွှားအရွယ်အစားနှင့် ထုတ်လုပ်မှုလိုင်းကို ပံ့ပိုးပေးသည်။

အသေးစိတ်ကြည့်ရှုပါ။ဘူတာရုံတစ်ခုလုံးကို ရှာဖွေပါ။

In the field of moringa powder processing, most grinding equipment is still limited by the drawback of single – raw material compatibility. A separate set of equipment is required for processing moringa leaves, and the components need to be re – adjusted for grinding moringa seeds. This not only reduces production efficiency, but also significantly increases equipment investment and operation and maintenance costs.

However, the moringa powder grinding machine developed by Pcreate Machinery fundamentally breaks this industry limitation. Without replacing any grinding parts, one single machine can seamlessly meet the grinding requirements of both moringa leaves and moringa seeds. This core advantage achieves a dual improvement in the raw material utilization rate and production flexibility of moringa processing.

More importantly, on the basis of dual – raw material compatibility, Pcreate Machinery’s moringa powder grinding machine is equipped with high – speed and low – temperature – rise grinding technology. It not only ensures the grinding efficiency of ultra – fine and uniform moringa powder, but also effectively locks in the thermosensitive nutrients in moringa leaves and seeds, making it no longer a choice between efficient production and quality preservation.

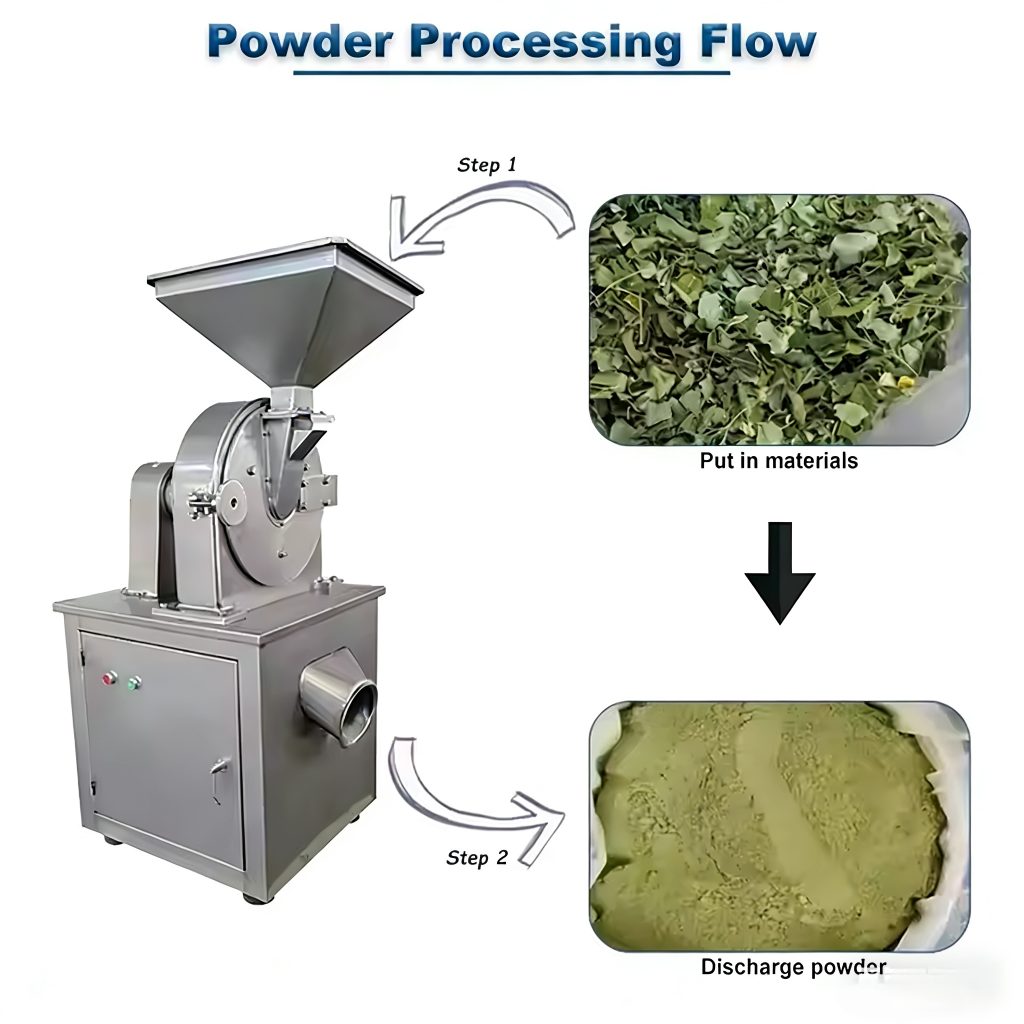

When selecting a moringa powder grinding machine, the key is to match the characteristics of moringa materials—dry, lightweight, and slightly fibrous. A high-quality grinder should efficiently and finely grind these moringa materials into powder, while also being easy to clean and maintain. Below is a detailed introduction to our company’s moringa powder grinding machines.

Our moringa powder grinding machine, also known as the toothed disc type moringa powder grinding machine, generates strong shearing and grinding forces through two toothed discs. It tears and grinds materials into fine powder, making it particularly suitable for processing fibrous materials such as dried moringa leaves or seeds.

| မော်ဒယ် | Capacity (kg/h) | Grinding Fineness (mesh) | Motor Power (kW) | Overall Dimensions (mm) | ဓာတ်အား |

| 300 | 60–150 | 10–120 | 4 | 2750×1300×2850 | 220V/380V |

| 400 | 200–400 | 10–120 | 7.5 | 3450×1300×2850 | 380V |

| 500 | 300–500 | 10–120 | 11 | 3500×1300×2850 | 380V |

| 600 | 400–600 | 10–120 | 15 | 3570×1300×2850 | 380V |

| 800 | 500–1000 | 10–120 | 22 | 3850×1300×2850 | 380V |

| Specification | Model 300 | Model 400 |

| Recommended Positioning | Small business start-up / flexible production | Main equipment for small businesses / stable production |

| အလုပ်အခြေခံ | Toothed disc type (high-speed shearing between movable and fixed toothed discs) | Toothed disc type (high-speed shearing between movable and fixed toothed discs) |

| Output (kg/h) | 60–150 | 200–400 |

| မော်တော်ပါဝါ | 4 kW | 7.5 kW |

| Discharge Fineness (Mesh) | 10–120 mesh (adjustable) | 10–120 mesh (adjustable) |

| အဓိက အားသာချက်များ | 1. High cost performance with low initial investment 2. Compact footprint and robust structure 3. Suitable for medium-low output or production with frequent material switching | 1. Optimal balance between capacity and versatility 2. Especially suitable for fibrous materials like moringa 3. Reserved capacity for future production expansion |

| Specification | Model 400 | Model 600 | Model 800 |

| Core Type | Upgraded toothed disc type (equipped with dust removal system) | Upgraded toothed disc type (equipped with dust removal system) | Upgraded toothed disc type (equipped with dust removal system) |

| Output (kg/h) | 300–500 | 400–600 | 500–1000 |

| Discharge Fineness (Mesh) | 10–120 mesh (adjustable) | 10–120 mesh (adjustable) | 10–120 mesh (adjustable) |

| မော်တော်ပါဝါ | 7.5 kW | 15 kW | 22 kW |

| Key Features | 1. Robust structure with relatively easy maintenance 2. Equipped with cyclone dust removal system or pulse dust removal system for workshop-friendly environment 3. Optimized for fibrous materials (moringa) with high cost performance | 1. Robust structure with relatively easy maintenance 2. Equipped with cyclone dust removal system or pulse dust removal system for workshop-friendly environment 3. Optimized for fibrous materials (moringa) with high cost performance | 1. Large output, ideal for scaled production 2. Precisely adjustable fineness with concentrated particle size distribution for high-quality powder 3. More complex system with larger footprint and higher initial investment |

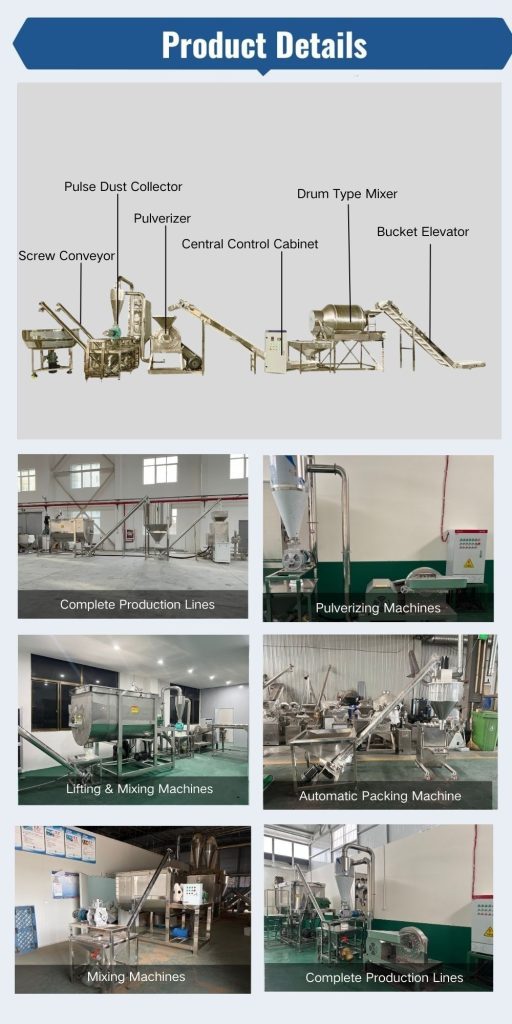

If you operate a large-scale moringa powder processing plant and require scaled production with an hourly output of over 1 ton, we recommend our Moringa Powder Production Line.

This production line features continuous automated operation, high processing speed, large output, and superior product quality. The process flow is as follows: dried moringa materials (after harvesting) go through grinding, mixing, and packaging to produce finished moringa powder. The complete set of processing equipment includes Moringa Powder Grinding Machine, mixer, packaging machine, and other auxiliary device, which are ideal for the deep processing of moringa leaves, moringa leaf powder, and related products. In addition, this production line is also suitable for processing a wide range of food and condiments, such as coffee beans, chili peppers, and white granulated sugar.

| Item No. | Equipment Name | ပါဝါ | အတိုင်းအတာ (မီလီမီတာ) | Output |

| 1 | Moringa Powder Grinding Machine | 15 kW | 4450×950×2750 | 1000 kg/h |

| 2 | Moringa Powder Mixer | 11 kW | 2880×1200×2200 | 1000 kg/h |

| 3 | Moringa Powder Packaging Machine | 1.5 kW | 800×750×2100 | 5–30 bags/min |

| 4 | Moringa Powder Elevator | 3 kW | 810×870×800 | 1000 kg/h |

Note: The moringa powder processing line can be customized according to customer requirements.

Yes, it can generally grind most common, dry herbs. It is also suitable for processing other herbs, foods, and spices with similar physical properties (dry, crisp, and hard). However, there are slight differences in processing herbs of different types and characteristics. You can refer to the table below to determine which category your herbs belong to:

| Herb Categories & Characteristics | Common Examples | Grinding Recommendations & Precautions |

| Suitable for Grinding (Common dry herbs) | Astragalus membranaceus, Licorice Root, Panax Notoginseng, Angelica Sinensis | General Principles: Ensure the herbs are completely dry. Do not fill the grinder beyond 2/3 of its capacity. Adopt the intermittent “short-time, multiple passes” grinding method. |

| Needing Special Attention (Herbs containing oil/sugar/volatile components) | High sugar/gum content: Wolfberry, Prepared Rehmannia Root, Chinese Date Volatile oil content: Mint, Dried Tangerine Peel, Nutmeg Chemical granular materials: Urea, Chemical Fertilizer | 1.Anti-adhesion: Fully dry the materials, use a small amount per batch, and clean the grinder immediately after grinding. 2. Overheating Prevention: The intermittent “short-time, multiple passes” grinding method must be used to avoid the volatilization of active ingredients. 3. High-hardness Handling: Grinding time may be slightly longer; be sure to operate intermittently to prevent machine overload. |

| Prohibited for Grinding | Moist/greasy materials, flammable and explosive substances | May damag |

The core breakthrough of the moringa powder grinding machine produced by Pcreate Machinery lies in its one-machine compatibility with both moringa leaves and seeds—no need for part replacement. This resolves the long-standing industry pain points of low efficiency and high costs caused by the physical property differences between raw materials. Meanwhile, its high-speed, low-temperature-rise technology achieves ultra-fine grinding while effectively preserving heat-sensitive nutrients, striking a perfect balance between efficient production and quality assurance.

The Model 400 standalone version of the moringa powder grinding machine manufactured by Pcreate Machinery is the ideal choice. This machine delivers a production capacity of 100–300 kg/h, achieves a grinding fineness of 10–120 mesh, and features a compact footprint.

Yes. Moringa materials must be completely dried prior to grinding to prevent caking, mold growth, and machine clogging during the grinding process.

The fineness of moringa powder can be adjusted by replacing the screen with different aperture sizes.

You can either install a dust removal device at the rear end of the grinder or directly purchase a moringa powder grinding machine equipped with an integrated dust removal system.

Yes. In addition to all types of moringa raw materials, this grinder can also process dry herbs, spices, and food ingredients, such as coffee beans, cocoa beans, dried banana slices, white granulated sugar, etc.

Pcreate Machinery specializes in complete sets of equipment for the powder processing industry, covering the entire production chain from single-unit machines to integrated systems—including crushing, conveying, mixing, screening, and granulation. Our products serve a wide range of sectors, such as food additives, baking ingredients, pharmaceutical intermediates, health food, and chemical raw materials.

Backed by advanced technologies, sophisticated craftsmanship, and a comprehensive pre-sales service system, we have earned consistent praise from customers both at home and abroad. We prioritize establishing long-term partnerships with clients, and have witnessed the growth of numerous customers through our top-tier product quality နှင့် dedicated service.

We firmly believe that quality and efficiency are reflected in every detail—from engineering design, R&D experiments, to equipment manufacturing, installation, and commissioning. We strive to optimize every step to ensure our machines perform at their peak.

ချောကလက်၊ အစားအစာနှင့် အဖျော်ယမကာ ပြုပြင်ခြင်းအတွက် သင့်လျော်သော ကိုကိုးစေ့ကြိတ်စက်သည် မြင့်မားသော ထိရောက်မှု၊ တူညီသော အမှုန်အမွှားအရွယ်အစားနှင့် ထုတ်လုပ်မှုလိုင်းကို ပံ့ပိုးပေးသည်။

အသေးစိတ်ကြည့်ရှုပါ။The seaweed grinding machine is a high-efficiency powder processing equipment specifically designed for fibrous seaweed materials. It is suitable for grinding various dried seaweed raw materials such as kelp, nori, wakame, and spirulina. Addressin...

အသေးစိတ်ကြည့်ရှုပါ။Our ultra fine grinder delivers uniform, ultra-fine powder for spice, herb, food and chemical industries. Customizable for your material.

အသေးစိတ်ကြည့်ရှုပါ။In the production processes of chemical, food, pharmaceutical and other industries, the uniform mixing of powder materials is a core link to ensure product quality. Relying on its unique structural design, high-efficiency mixing capacity and wide ...

အသေးစိတ်ကြည့်ရှုပါ။ဤဝဘ်ဆိုက်သည် သင်၏ရှာဖွေမှုအတွေ့အကြုံကို မြှင့်တင်ရန် ကွတ်ကီးများကို အသုံးပြုသည်။ ဤဆိုက်ကို ဆက်လက်အသုံးပြုခြင်းဖြင့်၊ ကျွန်ုပ်တို့၏ cookies များကို သင်လက်ခံပါသည်။ ဤဝဘ်ဆိုက်မှ စုဆောင်းရရှိသော အချက်အလက်များကို အမေရိကန်ပြည်ထောင်စုတွင် စီမံဆောင်ရွက်ပြီး သိမ်းဆည်းထားသည်။