Sugar Grinder Complete Guide: Principles, Usage, Selection & Applications

1501The sugar grinder is used in the production and processing of biscuits, cakes, coffee, milk powder, jams, potato chips and other products.

အသေးစိတ်ကြည့်ရှုပါ။ဘူတာရုံတစ်ခုလုံးကို ရှာဖွေပါ။

Do you want to efficiently and reliably grind seaweed into high-quality powder, but are constantly plagued by tangling, clogging, or dust issues? Choosing the right seaweed pulverizer can ensure continuous and stable operation of your production line, provide uniform and controllable powder particle size, and easily handle various seaweed raw materials, from kelp to spirulina. Whether in the food, health products, cosmetics, or feed industry, this grinder, specifically designed for seaweed, is a key tool for achieving high yield, high quality, and high efficiency.

How to choose the best seaweed powder grinding machine?

What are the four types of seaweed grinding machines?

Is seaweed powder difficult to grind?

What mesh size can seaweed powder be ground to?

What is the hourly production capacity of the seaweed powder grinding machine?

Does the machine generate high temperatures when grinding seaweed powder?

Can the seaweed powder grinding machine achieve continuous and stable operation?

အမြဲမေးလေ့ရှိသောမေးခွန်းများ

Summary and Conclusion

About Pcreate

With the global demand for seaweed products continuously rising, seaweed powder is increasingly used in food, dietary supplements, animal feed, cosmetics, and agriculture. However, due to its fibrous, lightweight, and easily entangling nature, grinding seaweed is much more challenging than grinding ordinary grains or herbs. Choosing the right seaweed grinder is crucial for ensuring powder quality, production efficiency, and long-term stable operation.

Seaweed contains long and tough fibers that can easily wrap around blades and shafts, causing blockages and unstable operation in traditional grinders. Dry seaweed is light and fluffy, making feeding and discharge more difficult without proper airflow and cyclone separation.

To achieve the best grinding results, it is important to select a grinder that suits your specific seaweed material. Additionally, seaweed should be dried to below 10% moisture content, as excessive moisture can lead to clumping, blockage, and reduced efficiency.

Working Principle: High-speed rotating discs cut, impact, and grind seaweed into granules or powder.

Suitable Seaweed: Seaweed with long fibers and flexible texture, such as kelp and wakame.

Features:

Working Principle: High-speed rotating hammers impact seaweed, breaking it into small granules or powder.

Suitable Seaweed: Medium-hardness seaweeds such as nori and kelp.

Features:

Working Principle: Uses pressing, impact, or rolling to crush seaweed into small pieces or coarse powder, preparing it for fine grinding.

Suitable Seaweed: Large-block or high-moisture seaweed such as kelp segments or wakame.

Features:

Working Principle: Uses high-speed airflow, impact, and friction to grind seaweed into ultra-fine powder, reaching micron-level particle size.

Suitable Seaweed: Spirulina, nori, and other seaweeds requiring high nutritional preservation.

Features:

Seaweed is more difficult to grind than grains because it is fibrous and lightweight. However, this seaweed grinderi specially designed for fibrous materials, making seaweed grinding stable and easy. Ordinary grinders may experience blockages, but our seaweed grinder uses an anti-entanglement cutting structure. As long as the seaweed is properly dried, the machine can operate continuously without clogging.

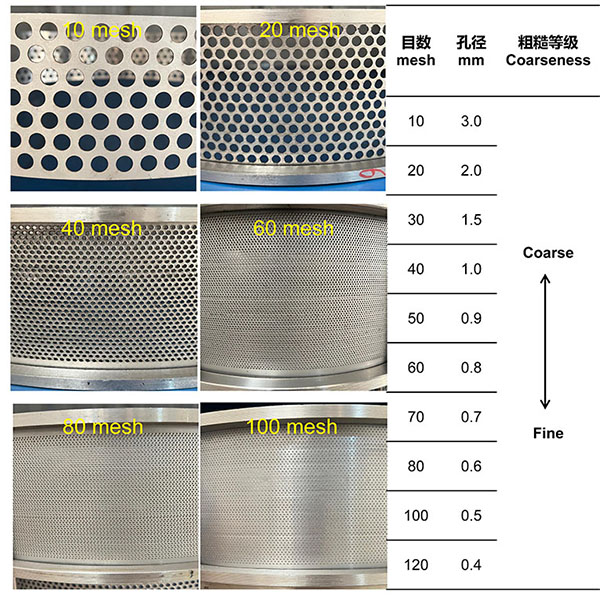

This stainless steel seaweed grinder can produce powders ranging from 10–120 mesh to meet various requirements:

The output depends on multiple factors, usually ranging from 20 kg/h to 2000 kg/h:

Actual capacity depends on: screen size, moisture content, and seaweed type.

| မော်ဒယ် | power | Engine speed | ကိုယ်အလေးချိန် | အရွယ်အစား | Yield | Loop diameter |

| 200 | 3kw | 7200r/min | 103kg | 670*385*980mm | 20-100kg/h | 200mm |

| 300 | 4kw | 5800r/min | 125kg | 520*1050*1065mm | 100-300kg/h | 295mm |

| 400 | 7.5kw | 4700r/min | 160kg | 1190*910*970mm | 200-500kg/h | 370mm |

| 500 | 11kw | 3920r/min | 226kg | 1260*1000*960mm | 300-600kg/h | 430mm |

| 600 | 15kw | 3930r/min | 270kg | 1370*1000*1050mm | 300-900kg/h | 510mm |

| 800 | 22kw | 2950r/min | 465kg | 1550*1150*1400mm | 800-2000kg/h | 667mm |

From a design perspective:

Key operational controls:

With proper design and complementary drying, feeding, and dust removal systems, the seaweed grinder can operate continuously and stably over long periods.

Q1: Can the seaweed grinderrun continuously?

Yes, provided it is properly designed and integrated into a complete processing system with automatic feeding, anti-entangling structure, and dust collection.

Q2: Which grinder is suitable for different types of seaweed?

Q3: What if the powder is uneven?

Q4: How to prevent fiber wrapping?

Q5: How to deal with dust and cleaning issues?

Choosing the right seaweed grinder is crucial for powder quality, production efficiency, and continuous operation. By understanding the types of grinders, proper preparation of seaweed, and operational best practices, businesses can achieve stable and high-quality production for food, supplements, cosmetics, and agriculture.

Pcreate Machinery provides complete powder processing solutions, covering crushing, conveying, mixing, sieving, and granulation. Our products serve industries such as food additives, bakery ingredients, pharmaceutical intermediates, health supplements, and chemical raw materials.

With advanced technology, precise engineering, and comprehensive pre-sales support, we have earned high praise from domestic and international clients. Pcreate focuses on long-term cooperation, delivering high-quality products and reliable service. We ensure excellence in design, R&D, production, and installation, attending to every detail to maximize machine performance.

Contact Pcreate today to assess your facility requirements and get a custom equipment configuration plan

The sugar grinder is used in the production and processing of biscuits, cakes, coffee, milk powder, jams, potato chips and other products.

အသေးစိတ်ကြည့်ရှုပါ။The Shrimp skin Ultrafine Pulverizer is essentially a stainless steel toothed disc pulverizer. Its crushing fineness can be flexibly adjusted (10 to 120 meshes), which can accurately adapt to the production needs of food, feed, biological processi...

အသေးစိတ်ကြည့်ရှုပါ။Moringa Powder Grinding Machine is suitable for crushing various moringa raw materials such as moringa seeds and moringa leaves. This Moringa Powder Grinding Machine is also applicable for milling a wide range of herbal medicines, as well as food ...

အသေးစိတ်ကြည့်ရှုပါ။This ribbon flour mixer has a pro ribbon mixing setup – mixes flour 360 degrees all around perfectly!

အသေးစိတ်ကြည့်ရှုပါ။ဤဝဘ်ဆိုက်သည် သင်၏ရှာဖွေမှုအတွေ့အကြုံကို မြှင့်တင်ရန် ကွတ်ကီးများကို အသုံးပြုသည်။ ဤဆိုက်ကို ဆက်လက်အသုံးပြုခြင်းဖြင့်၊ ကျွန်ုပ်တို့၏ cookies များကို သင်လက်ခံပါသည်။ ဤဝဘ်ဆိုက်မှ စုဆောင်းရရှိသော အချက်အလက်များကို အမေရိကန်ပြည်ထောင်စုတွင် စီမံဆောင်ရွက်ပြီး သိမ်းဆည်းထားသည်။