Send us a message

We would love to hear from youSubmit your question and our team will respond to the email provided as soon as possible.

Search the whole station

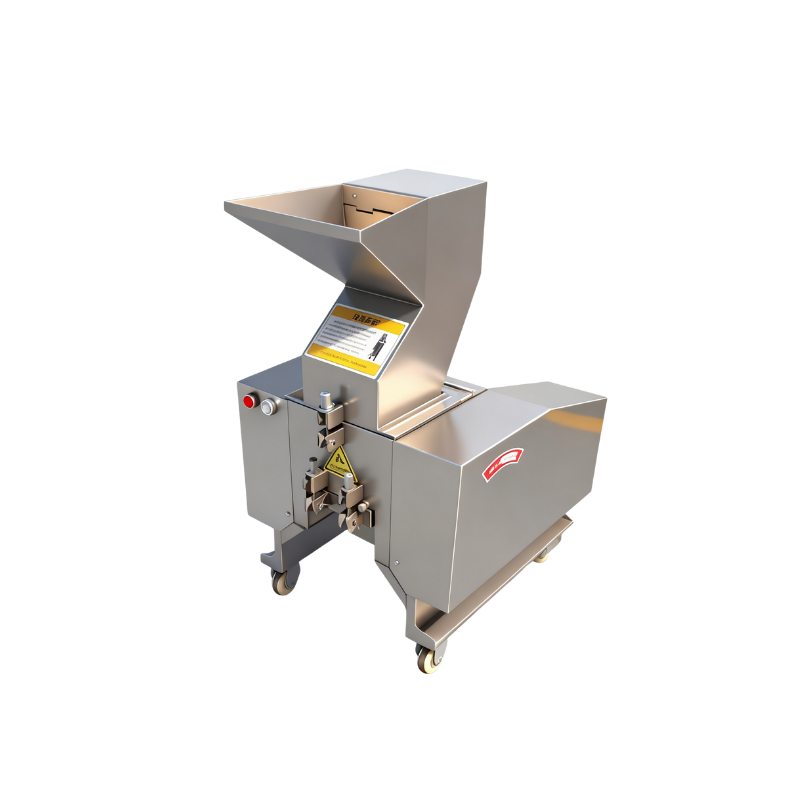

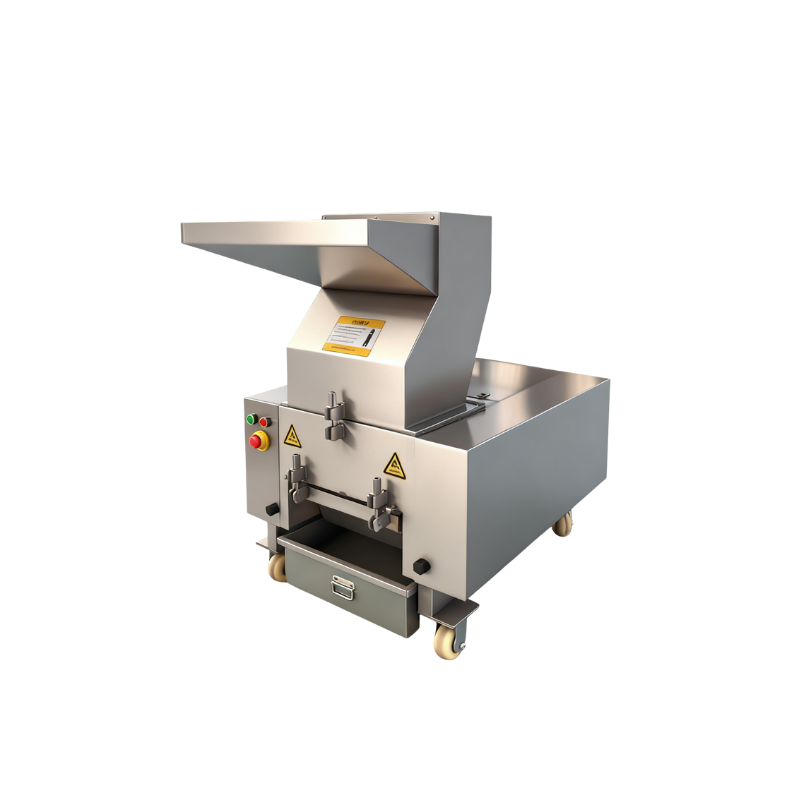

The Bone Crusher is an industrial machine designed to crush and grind animal bones into smaller pieces. It has a wide range of applications and can handle various frozen or fresh bones, including beef, pork, lamb, donkey, chicken, and even whole fish bones.

The Bone Crusher operates on a shear and crush mechanism. Its process is as follows:

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.