Search the whole station

A bucket elevator is a device designed for the vertical transport of bulk materials. It’s widely used in industries like grain processing, coal mining, ore handling, cement production, and fertilizer manufacturing.

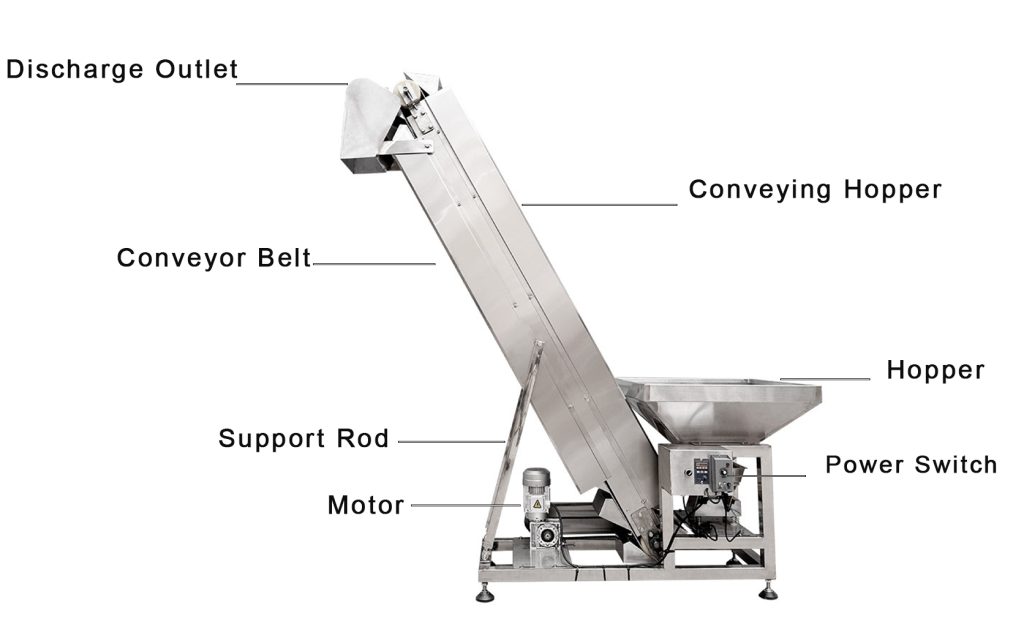

At its core, it uses a chain or belt fitted with multiple lifting buckets. As the chain/belt moves, these buckets scoop up materials and carry them vertically to a higher position. Bucket elevators can be customized based on factors like material type, lifting height, and handling capacity. Key advantages include a simple structure, stable operation, and reliable performance.

The working principle of a bucket elevator is straightforward, following a cyclic process:

Bucket elevators excel at vertical bulk material transport and are used across numerous industries:

They lift grains, powdered materials, and granular products to higher levels, facilitating subsequent processing, storage, or loading onto trucks/trains.

Ideal for vertically transporting cement, lime, coal powder, and other powdery/granular materials—playing a critical role in cement production lines.

In fertilizer manufacturing, bucket elevators move raw fertilizer materials and finished fertilizer products to different storage warehouses.

Commonly used to vertically transport ore, coal powder, and similar materials in coal mines and mineral mines. They adapt well to complex mine environments.

Essential for moving construction materials like stone chips and gravel during production.

As a popular material-lifting solution, bucket elevators offer several technical benefits:

Bucket elevator models and configurations vary based on material properties, lifting height, and handling capacity. Below are common options:

| Model | Handling Capacity | Lifting Height | Drive Method | Suitable Materials | Key Features |

|---|---|---|---|---|---|

| TD Series | 10–80 t/h | 10–40 meters | Electric motor | Fly ash, lime, sand, gravel, etc. | Works with multiple materials; stable performance |

| TH Series | 30–200 t/h | 10–50 meters | Electric motor or diesel engine | Grain, fertilizer, ore, etc. | Compact structure; easy to use |

| NE Series | 50–500 t/h | 15–60 meters | Electric motor | Ore, coal, metal ore, etc. | High efficiency; ideal for large-scale production |

| BL Series | 20–150 t/h | 10–30 meters | Electric motor | Grain, coal, etc. | Suitable for fine granular materials |

When choosing a bucket elevator, consider these critical factors:

During operation, you may encounter these common problems with bucket elevators:

The key to resolving these issues is regular maintenance and inspections, adjusting operating parameters as needed, and keeping the equipment running under normal load.

To ensure long-term stable operation of your bucket elevator, follow these tips:

Bucket elevators are versatile vertical transport devices widely used across industries. Their strengths—simple structure, small footprint, and strong adaptability—make them ideal for lifting bulk materials like grain, ore, coal, fertilizer, and cement efficiently.

When selecting a bucket elevator, align the model with your material properties, lifting needs, and space constraints. Additionally, prioritize regular maintenance and management to ensure stable long-term operation and lower production costs.

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.