Sugar Grinder Complete Guide: Principles, Usage, Selection & Applications

1614The sugar grinder is used in the production and processing of biscuits, cakes, coffee, milk powder, jams, potato chips and other products.

View detailsSearch the whole station

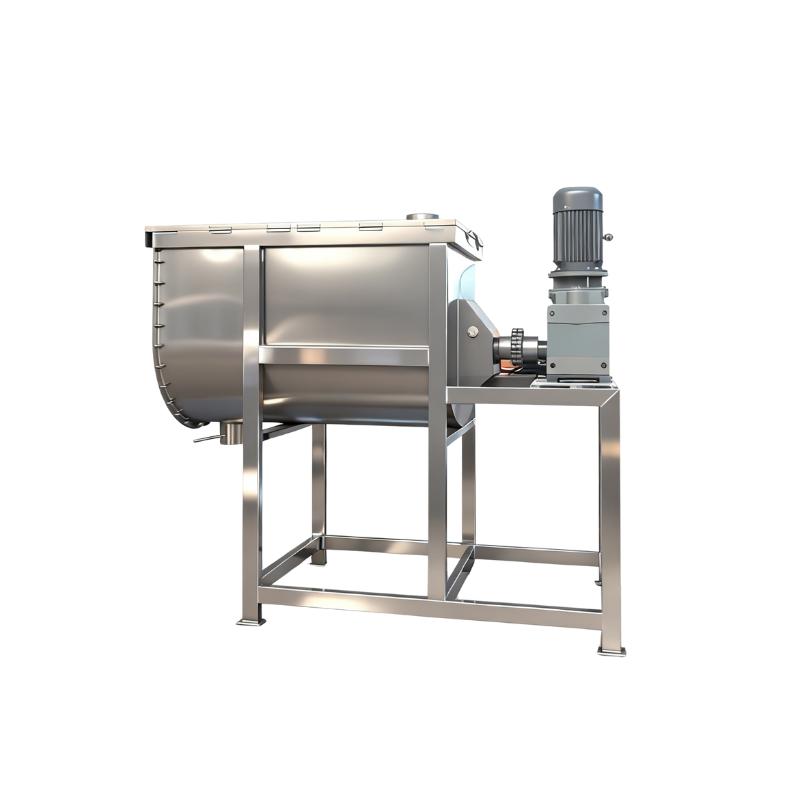

This ribbon blender is a high-efficiency mixing machine designed specifically for flour, premixed powder, and all kinds of grain powder materials. Made entirely of food-grade 304 stainless steel with top-notch craftsmanship, it meets national food safety standards perfectly. It mixes flour with various additives and modifiers evenly and precisely, and the mixing process is gentle enough to keep the original powder structure and gluten strength of the flour intact.

You’ll find this blender super useful in bakeries, noodle factories, automatic steamed bun/stuffed bun production lines, and professional premixed powder manufacturers. It’s basically the go-to equipment for upgrading the efficiency and quality of powder mixing.

The core of this ribbon blender is its horizontal barrel paired with a double ribbon mixing structure. The inner and outer ribbons spin in opposite directions, working together to move the flour — spreading it to both ends of the barrel while pulling it toward the center at the same time. This creates a 3D circular motion that mixes everything up well.

The whole process is gentle and energy-saving, no local high temperatures at all. That means the flour’s gluten, texture, and flavor stay totally unharmed — a big win for your final products!

The sugar grinder is used in the production and processing of biscuits, cakes, coffee, milk powder, jams, potato chips and other products.

View detailsCocoa bean grinder suitable for chocolate, food, and beverage processing, offering high efficiency, uniform particle size, and production line support.

View detailsThe seaweed grinding machine is a high-efficiency powder processing equipment specifically designed for fibrous seaweed materials. It is suitable for grinding various dried seaweed raw materials such as kelp, nori, wakame, and spirulina. Addressin...

View detailsIn the production processes of chemical, food, pharmaceutical and other industries, the uniform mixing of powder materials is a core link to ensure product quality. Relying on its unique structural design, high-efficiency mixing capacity and wide ...

View detailsThis website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.