Moinho de Grãos Eficiente - Moagem Fácil de Cereais

1319Moinho de grãos para moagem eficiente de cereais e grãos, garantindo um tamanho de partícula uniforme e apoiando as linhas de processamento de alimentos e de produção de rações.

Ver pormenoresPesquisar toda a estação

The Stainless Steel Star Anise Grinder is a piece of equipment designed for grinding and pulverizing spices. It can crush various seasonings such as Sichuan pepper, chili, star anise, cinnamon, bay leaves, cumin, fennel, nutmeg, etc. This grinder is a claw-type crusher made of 304 stainless steel, capable of achieving a fineness of up to 120 mesh. It is used for processing spices, grinding grains, and pulverizing chemical raw materials.

Working Principle The Stainless Steel Star Anise Grinder utilizes the high-speed relative motion between the movable and fixed toothed discs to impact, friction, and collide with the materials, thereby achieving pulverization. The crushed material is directly discharged from the grinding chamber through the outlet. Generally, after grinding, the material is collected using a cotton bag, which retains the fine powder while allowing air to escape through the tiny pores of the bag. This prevents powder waste and pollution. The particle size can be adjusted by changing sieves with different mesh sizes.

Configurations & Types The grinder now comes in various configurations:Feed Hopper:Can be horizontal or vertical.Use a vertical feed hopper for grain materials to prevent splashing and potential injury. Use a horizontal hopper** for free-flowing materials.Frame Type Flat-frame grinder:Has a lower feeding height, making it easier for manual feeding.Raised-frame grinder:Has a higher feeding height, allowing for the use of belt conveyors or screw conveyors for feeding, thus saving labor.

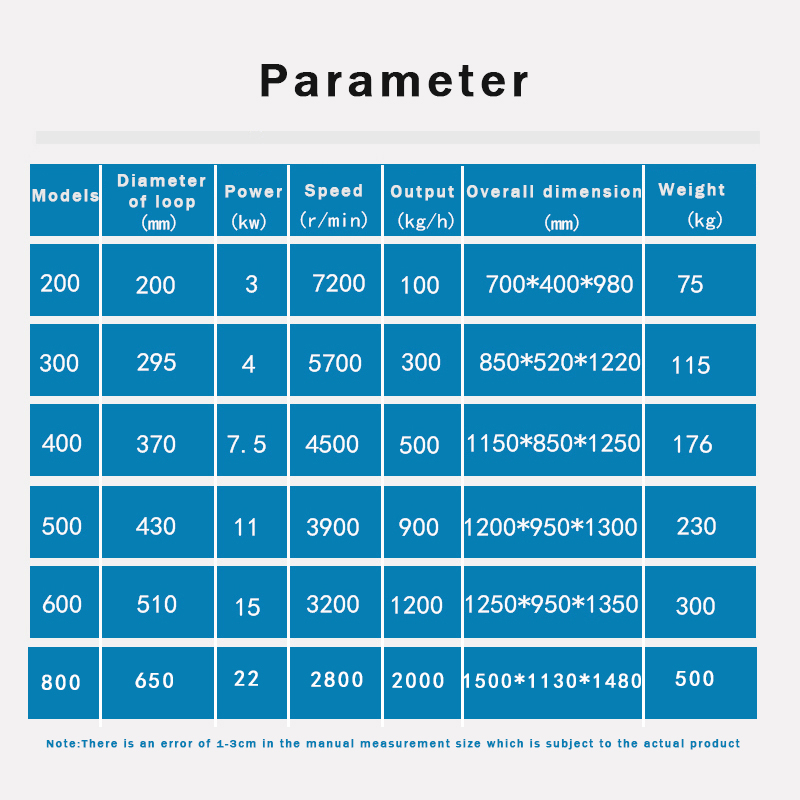

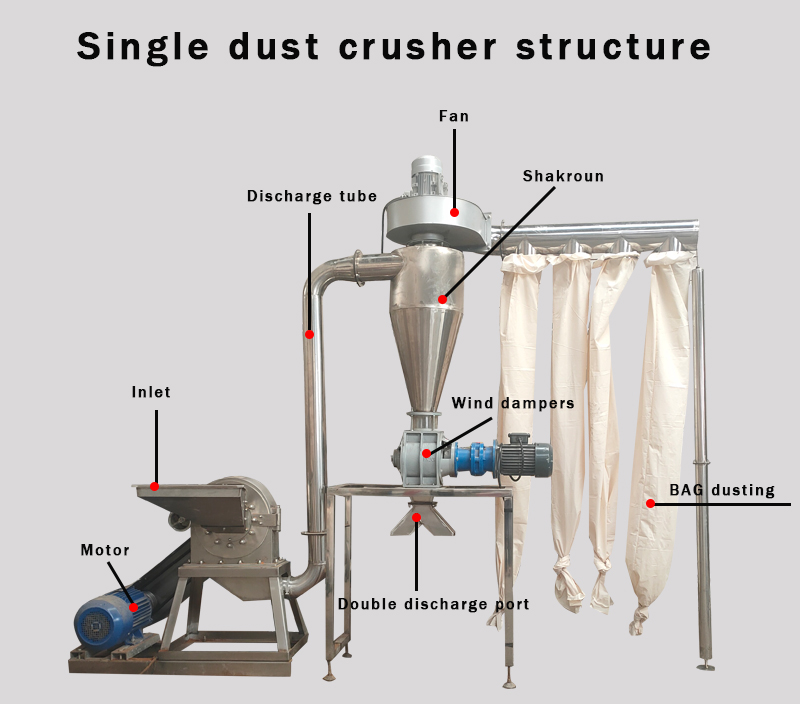

Model Classification Models of the Stainless Steel Star Anise Grinder include: 20, 30, 40, 50, 60, 80, 1000, single-dust-removal grinder, pulse-dust-removal grinder, and water-cooled grinder.Applications & Lines

This grinder can be used as a standalone unit or equipped with a cyclone dust collector or pulse dust collector. It can also be integrated with a U-shaped ribbon mixer, stainless steel elevator, and powder packaging machine to form a production line.

Features Strong crushing capacity Low energy consumption Relatively fine product granularity Large grinding chamber High-strength air pressure generated by the rotating blade disc enhances production capacity, reduces over-grinding, prevents material accumulation and clogging on the sieve, and helps dissipate heat. Sealing ring on the door prevents powder leakage during operation, increasing output and ensuring safety and environmental protection.Can be fitted with a self-suction pipe or screw conveyor for fast feeding and high grinding efficiency. The base features a thickened frame with an adjustable motor mount for enhanced stability.

Precautions 1. An appropriate circuit breaker should be installed based on the machine’s power rating to protect the motor by automatically cutting off the power in case of overload or excessive current.

Moinho de grãos para moagem eficiente de cereais e grãos, garantindo um tamanho de partícula uniforme e apoiando as linhas de processamento de alimentos e de produção de rações.

Ver pormenoresMisturador de amido de milho para mistura uniforme e processamento de pó de alta eficiência em linhas de produção alimentar, química e farmacêutica.

Ver pormenoresLinha completa de trituração de especiarias para processamento de alta eficiência, tamanho de partícula uniforme e produção optimizada nas indústrias alimentares e de condimentos.

Ver pormenoresExplore as vantagens dos moinhos de arroz para uma moagem uniforme, elevada eficiência e adequação em linhas de produção alimentar e de processamento de cereais.

Ver pormenoresEste sítio Web utiliza cookies para melhorar a sua experiência de navegação. Ao continuar a utilizar este sítio, o utilizador aceita a utilização dos nossos cookies. Os dados recolhidos neste sítio Web são processados e armazenados nos Estados Unidos.