Porque é que vale a pena escolher o moinho de arroz?

1524Explore as vantagens dos moinhos de arroz para uma moagem uniforme, elevada eficiência e adequação em linhas de produção alimentar e de processamento de cereais.

Ver pormenoresPesquisar toda a estação

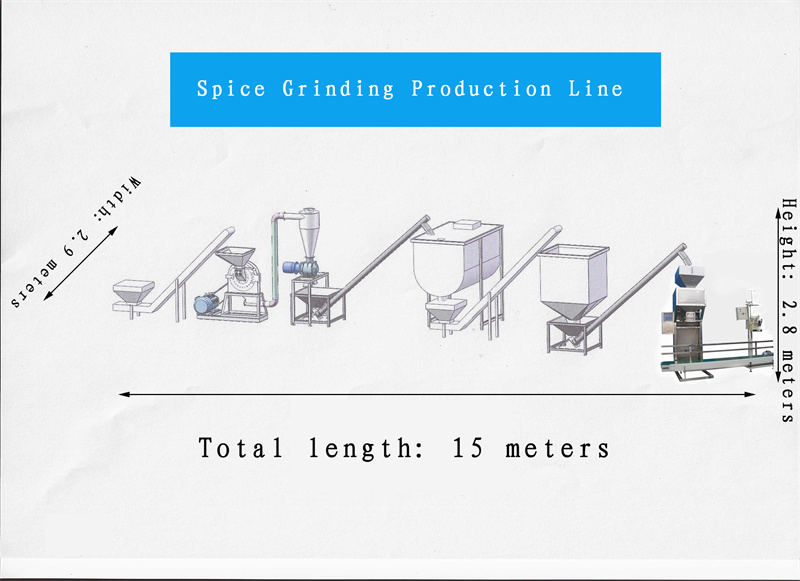

The spice crushing production line is a complete set of equipment used for crushing spices, including a coarse crusher, grinder, elevator, mixer, rotary vibrating screen, storage bin, and packaging machine. The spice crushing production line is no longer just a simple “grinding” tool; it is an integrated system for crushing, mixing, and packaging.

The spice crushing production line features high output, automated continuous production, significantly reduces labor costs, and meets large-scale market demands. The entire equipment is made of 304 stainless steel, which is corrosion and oxidation-resistant, ensuring a long service life. The production process of this line is roughly as follows:

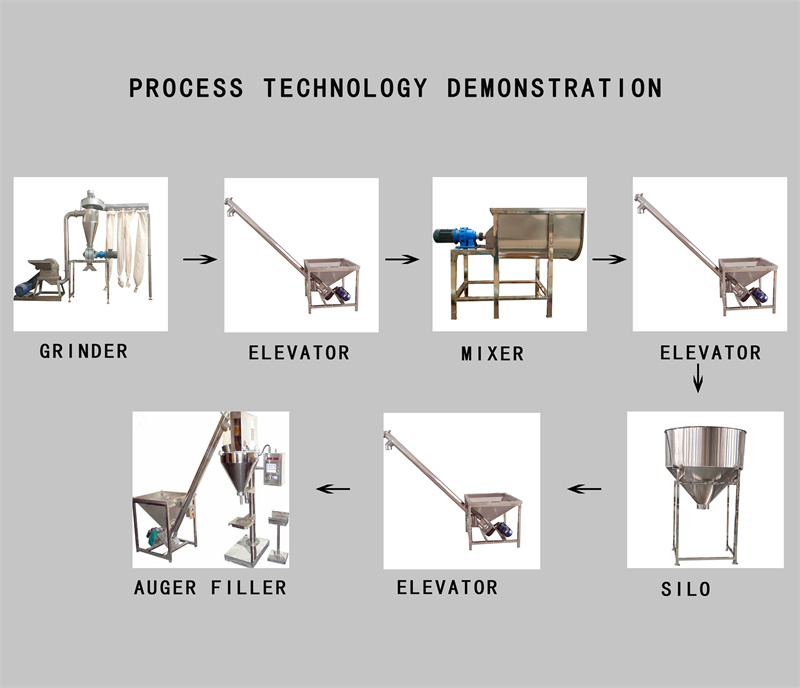

Alimentação — Using manual labor, a stainless steel screw elevator, or a skirt-edge belt feeder for feeding.

Crushing — If the raw material particle size is large during crushing, it can be coarsely crushed first and then finely ground. The grinder is equipped with a cyclone separator and a dust collector at the rear. The cyclone separator uses centrifugal force to separate and collect most of the material. Residual fine dust is collected by the rear pulse bag dust collector, ensuring no dust leakage, protecting the workshop environment, and improving raw material yield.

Mixing — The mixer can be a ribbon-type dry powder mixer, drum-type powder mixer, or滚筒式搅拌机 (drum mixer).

Rastreio — A rotary vibrating screen can be selected to screen out unqualified raw materials for re-crushing, improving the crushing effect.

Storage Bin — Acts as a buffer, allowing the screened raw materials to await packaging.

Packaging — Options include semi-automatic powder packaging machines, fully automatic powder packaging machines, or back-sealing packaging machines. The packaging range of these machines is adjustable, saving time and effort.

The spice crushing production line is suitable for processing condiments, grain processing, feed processing, medicinal material processing, and crushing other chemical raw materials. Different specifications of screens can be installed as needed to process materials of varying fineness. It is applicable in industries such as pharmaceuticals, chemicals, metallurgy, food, and feed. It can crush salt, monosodium glutamate (MSG), chicken bouillon, seasonings, chili peppers, star anise, Sichuan peppercorns, cinnamon, bay leaves, cumin, large spices (dàliào), spices, fennel, green Sichuan peppercorns (májiāo), green peppers, bell peppers, nutmeg, Atractylodes macrocephala (Bái Zhú), Angelica dahurica (Bái Zhǐ), dried turmeric, ginger, yam, dried tangerine peel (Chénpí), grains (wheat, corn, rice), barley, highland barley, glutinous rice, soybeans, mung beans, black beans, red beans, white sugar, rock sugar, maltose, brown sugar, glucose, dried goji berries, mulberries, monk fruit, chrysanthemums, floral tea, dark tea, licorice root, Poria cocos (Fúlíng), etc.

Precautions for using the spice crushing production line. To fix the stationary tooth disk, simply tighten the bolts. To remove the bearing, first open the machine chamber, remove the rotating tooth disk or rotary blade, take off the material blocking ring and hole retaining ring (or mǐgōng and center bearing cover), then remove the outer end pulley and bearing cover, and push the shaft out from both ends to remove the bearings and shaft from both ends. During installation, ensure the shaft bushing hole remains aligned with the oil hole. When installing the screen ring, the screen ring must fit tightly against the shoulder groove inside the machine chamber; otherwise, closing the door may damage the screen ring. For making the screen ring, the unfolded length of the screen mesh should be based on the diameter of the two inner shoulders multiplied by π (pi) plus a 12 mm edge length for crimping, with a 5 mm crimp. The width should be based on the opening size between the two inner shoulders and should be corrected after production. Installing the screen mesh: When combining the two screen ring pieces, align the marks, then press the screen mesh into the inner screen ring. If the screen mesh is too tight, it can be bent inward, pressed in, and then pushed outward.

Explore as vantagens dos moinhos de arroz para uma moagem uniforme, elevada eficiência e adequação em linhas de produção alimentar e de processamento de cereais.

Ver pormenoresMoedor de grãos de cacau adequado para processamento de chocolate, alimentos e bebidas, oferecendo alta eficiência, tamanho de partícula uniforme e suporte à linha de produção.

Ver pormenoresTriturador de sal em aço inoxidável para trituração de alta eficiência de sais e minerais, garantindo um tamanho de partícula uniforme para as indústrias alimentar e química.

Ver pormenoresMoedor de anis estrelado para moagem de especiarias de alta eficiência e uniforme, adequado para linhas de produção de alimentos, ervas e temperos.

Ver pormenoresEste sítio Web utiliza cookies para melhorar a sua experiência de navegação. Ao continuar a utilizar este sítio, o utilizador aceita a utilização dos nossos cookies. Os dados recolhidos neste sítio Web são processados e armazenados nos Estados Unidos.