What is a Rotary Drum Powder Mixer?

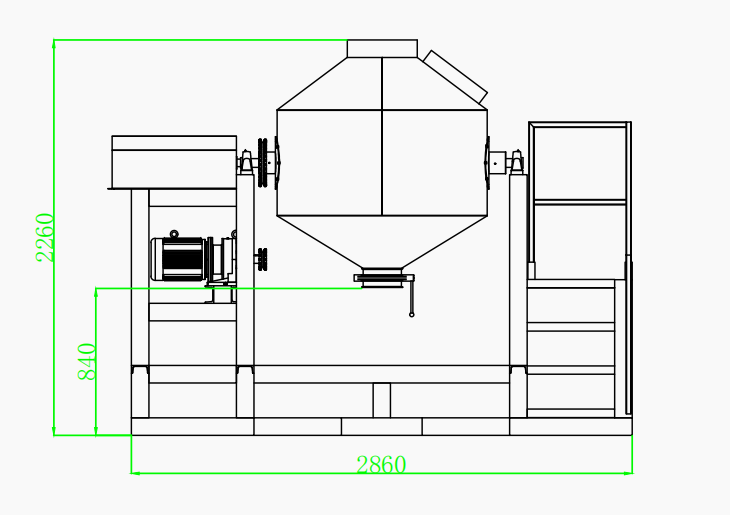

A Rotary Drum Mixer, as the name suggests, features a core mixing container (the “drum”) that rotates around its axis. Driven by a transmission system, the mixing drum performs a smooth rotational motion. This causes the internal powder materials to undergo continuous diffusion, convection, and shear movements under the combined actions of gravity, centrifugal force, and friction, thereby achieving comprehensive and uniform mixing.

This design is simple yet highly efficient, making it particularly suitable for materials that require high mixing gentleness, contain fragile particles, or where heat generation must be avoided.

Core Technical Advantages: Why Choose a Rotary Drum Mixer?

1. Unmatched Mixing Uniformity

- Principle: Powder is continuously lifted and cascaded within the rotating drum, forming a continuous “waterfall” motion. This three-dimensional movement ensures all particles have equal opportunity to participate in mixing, completely eliminating common dead zones found in static mixers.

2. Extremely Gentle Mixing Action

- Unlike traditional high-speed agitation or shear mixing, rotary drum mixing primarily relies on gravitational force. This gentle handling method maximizes the preservation of the material’s original particle morphology, preventing the breakage of fragile particles or destruction of crystal structures. This is crucial for protecting active ingredients or delicate powder forms.

3. Thorough Cleaning & No Cross-Contamination

- The interior of the mixing drum is typically smooth and free of dead ends, making cleaning extremely straightforward. This is vital for complying with GMP standards in the pharmaceutical and food industries. Many models support CIP (Cleaning-In-Place) and SIP (Sterilization-In-Place), ensuring no residue or contamination between batches.

4. Wide Range of Material Adaptability

- Whether it’s metal powders with significant differences in density, fine powders with poor flowability, or solid-liquid mixing requiring the addition of small amounts of liquid, the rotary drum mixer can handle them effectively. By adjusting rotation speed and mixing time, it can easily adapt to various process requirements.

5. High Loading Capacity & Efficiency

- The loading capacity of the mixing drum typically reaches 50% to 70% of its volume, achieving high space utilization. Simultaneously, the mixing process is fast and efficient, significantly shortening production cycles and enhancing overall capacity.

6. Low Energy Consumption & Low Maintenance

- Simple structure and stable transmission result in much lower operating energy consumption compared to high-speed mixing equipment. Furthermore, fewer moving parts and the gentle working method lead to reduced equipment wear and lower maintenance costs.

Main Application Fields

- Pharmaceutical Industry: Mixing of active pharmaceutical ingredients (APIs) and excipients; powder pre-mixing for tablets and capsules.

- Food Industry: Mixing of spices, seasonings, milk powder, flour additives, instant beverages.

- Chemical Industry: Preparation of dyes, pigments, plastic masterbatches, catalysts.

- New Energy: Uniform mixing of cathode and anode materials for lithium-ion batteries.

- Metal Manufacturing: Metal powder metallurgy; preparation of materials for 3D printing.

Features of Our Equipment (Can be customized based on your specific product)

Our series of Rotary Drum Powder Mixers integrate modern designs beyond traditional advantages:

Diverse Customization Options: Available in various materials (e.g., 304/316L stainless steel), with optional add-ons such as liquid spray devices, vacuum drying functions, and jacketed heating/cooling systems to meet your specific process needs.

Ergonomic Design: Utilizes human-engineered tilted or V-shaped drums, which not only improve mixing efficiency but also enable faster and more complete discharge.

Intelligent Control System: Equipped with a PLC touchscreen control system for precise setting and storage of parameters like rotation speed, time, and direction, ensuring reproducible processes for every batch.

Safety Assurance: Includes safety interlock devices that prevent the cover from being opened during operation, ensuring operator safety.