Search the whole station

What is a Rotary Drum Screen?

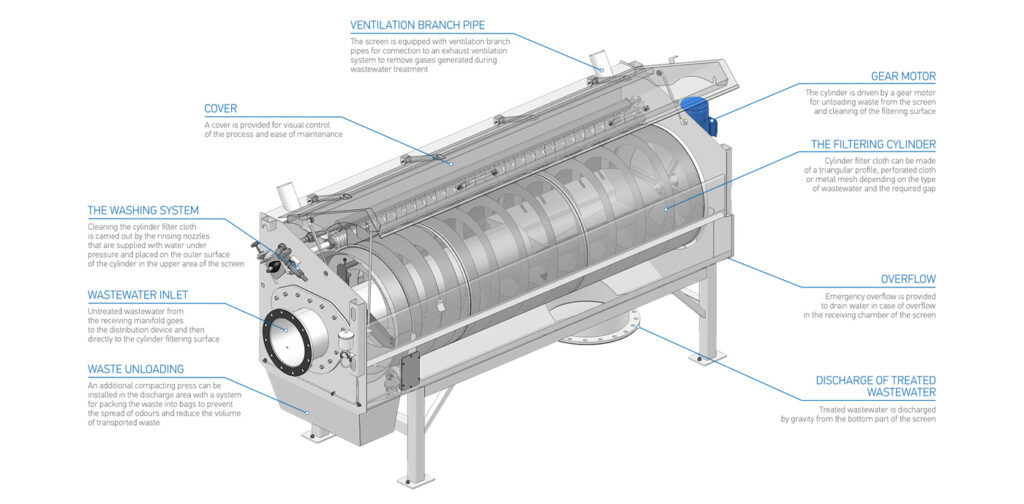

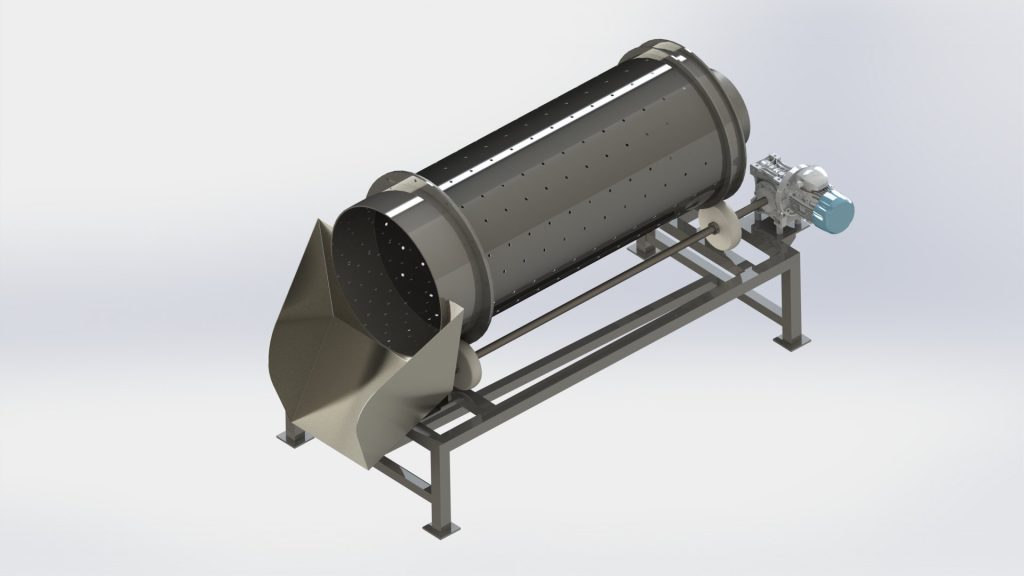

A rotary drum screen is a mechanical filtration device designed for solid-liquid separation, commonly used in wastewater treatment, food processing, chemical production, and various industrial processes.

It efficiently removes suspended solids, fibers, and particles from liquids through a continuously rotating drum fitted with a fine mesh or perforated plate.

The drum screen provides stable, automatic filtration, low maintenance, and continuous operation, making it ideal for high-capacity production lines.

In a typical production process:

Raw Material → Washing / Separation → Rotary Drum Screen → Filtrate → Next Processing Step

The rotary drum screen acts as a pre-treatment or separation station by:

Removes suspended solids, fibrous materials, and residues from liquids with high precision.

The rotating drum allows 24/7 filtration with self-cleaning function, minimizing downtime.

Designed with quick-access covers and modular parts for easy cleaning and inspection.

Ensures consistent particle removal and stable flow rate throughout the process.

Low power consumption and high throughput make it suitable for large-scale industrial applications.

| Structure Type | Drum Material | Mesh Type | Cleaning Method |

|---|---|---|---|

| Open Drum Type | SS304 / SS316L | Wedge Wire | Backwash Spray |

| Enclosed Type | SS316L | Perforated Plate | Brush + Rinse |

| Inclined Type | Carbon Steel | Wire Mesh | Rotary Cleaning System |

| Model | Drum Diameter (mm) | Length (mm) | Mesh Size (mm) | Material | Capacity (m³/h) | Application |

|---|---|---|---|---|---|---|

| RDS-600 | 600 | 1000 | 0.3 | SS304 | 5–15 | Food, Beverages |

| RDS-800 | 800 | 1200 | 0.5 | SS304 | 10–25 | Wastewater |

| RDS-1000 | 1000 | 1500 | 1.0 | SS316L | 20–40 | Chemical |

| RDS-1200 | 1200 | 2000 | 2.0 | SS316L | 30–60 | Pulp, Paper |

As a crucial solid-liquid separation device, the Rotary Drum Screen ensures smooth and efficient operation of industrial production lines.

It improves product quality, reduces maintenance costs, and enhances automation levels across multiple industries.

Whether for food, wastewater, or chemical applications, it stands as a reliable and energy-efficient solution for continuous filtration and solid removal.

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.