Search the whole station

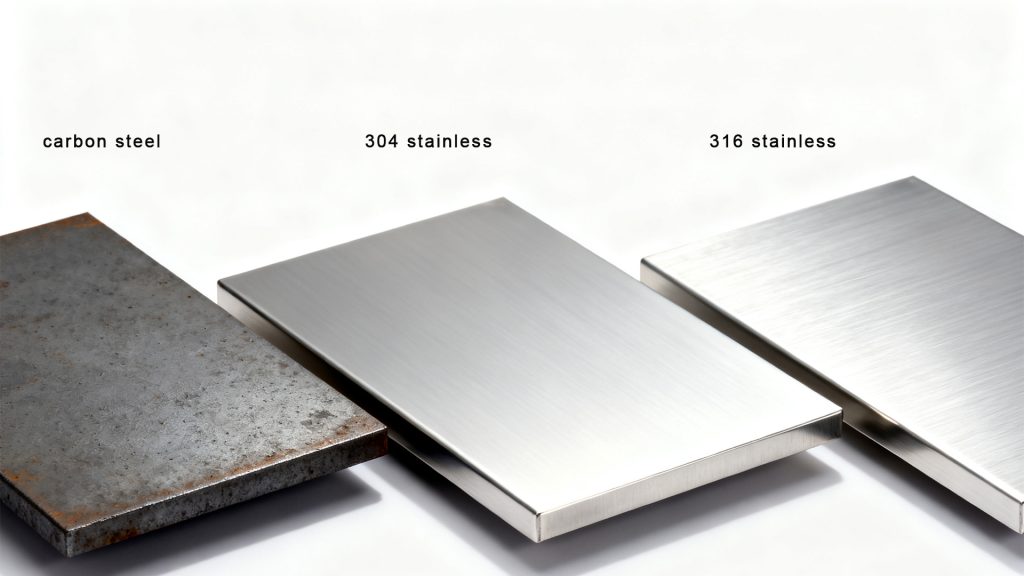

A storage silo is an auxiliary device designed for temporary storage and buffering of bulk materials, commonly used in powder and granule production lines. It is usually made of carbon steel or stainless steel, providing stable storage, controlled discharging, and seamless connection to the next process.

In a typical production process:

Grinding → Mixing → Elevating → Silo → Elevating → Packaging.

The silo serves as a buffering station by:

| Model | Capacity (m³) | Material | Discharge Type | Applications |

| Silo-2 | 2 | SS304 | Screw Conveyor | Food, Pharma |

| Silo-5 | 5 | Carbon Steel | Pneumatic Gate | Chemicals, Feed |

| Silo-10 | 10 | SS316L | Vibrating Discharge | Spices, Additives |

| Silo-20 | 20 | Carbon Steel | Screw + Gate Combined | Building Materials |

As an auxiliary device in production lines, a silo not only provides buffering and transition but also enhances continuity and automation. It has become an essential part of powder and granule processing systems.

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.