Search the whole station

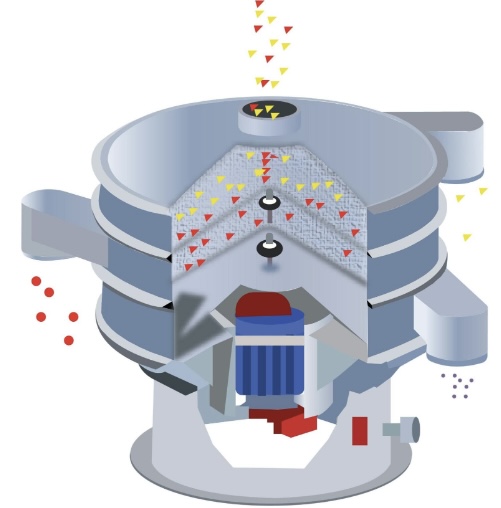

A vibrating screen is a type of mechanical equipment that uses the principle of vibration to separate granular or powdered materials into different grades based on their particle size.

A typical vibrating screen is usually made up of these key parts:

Here’s the lowdown on its working process—it’s simpler than you might think:

| Model | Effective Sieving Diameter (mm) | Effective Sieving Area (㎡) | Screen Specification | Layer Quantity | Vibrating Motor (kw) | Common Motor (kw) |

|---|---|---|---|---|---|---|

| HCZDS-600 | 540 | 0.2289 | 2-500 Mesh/inch | 1-4 storey | 0.25 | 0.75 |

| HCZDS-800 | 730 | 0.4183 | 2-500 Mesh/inch | 1-4 storey | 0.55 | 1.1 |

| HCZDS-1000 | 900 | 0.6359 | 2-500 Mesh/inch | 1-4 storey | 0.75 | 1.5 |

| HCZDS-1200 | 1100 | 0.9499 | 2-500 Mesh/inch | 1-4 storey | 1.1 | 1.5 |

| HCZDS-1500 | 1400 | 1.5386 | 2-500 Mesh/inch | 1-3 storey | 1.5 | 2.2 |

| HCZDS-1800 | 1700 | 2.2687 | 2-500 Mesh/inch | 1-3 storey | 2.2 | 3.0 |

| HCZDS-2000 | 1886 | 2.7922 | 2-500 Mesh/inch | 1-3 storey | 3.0 | 3.0 |

Vibrating screens stand out in material screening thanks to their unique design and operation—here are their main perks:

Vibrating screens are super versatile—you’ll find them in lots of industries, such as:

If you’re on the fence about whether to use one, here are the top reasons it’s a solid pick:

1.Works with Continuous Feeding: It can take materials fed continuously, and it’s easy to pair with other processing equipment (like conveyors or mixers) to build a full production line.

2.Simple Structure, Easy Maintenance: It doesn’t have complicated parts, so if something goes wrong, fixing or maintaining it is relatively hassle-free.

3.Less Screen Blockage: The screen box vibrates strongly, which stops materials from getting stuck in the mesh holes—no more frequent pauses to clear clogs.

4.Multi-Purpose Use: One machine can handle all sorts of materials, from fine powders to coarse granules—no need to buy separate equipment for different tasks.

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.