Máy xay hạt ca cao đa năng

1296Máy xay hạt ca cao thích hợp cho chế biến sô cô la, thực phẩm và đồ uống, mang lại hiệu suất cao, kích thước hạt đồng đều và hỗ trợ dây chuyền sản xuất.

Xem chi tiếtTìm kiếm toàn bộ nhà ga

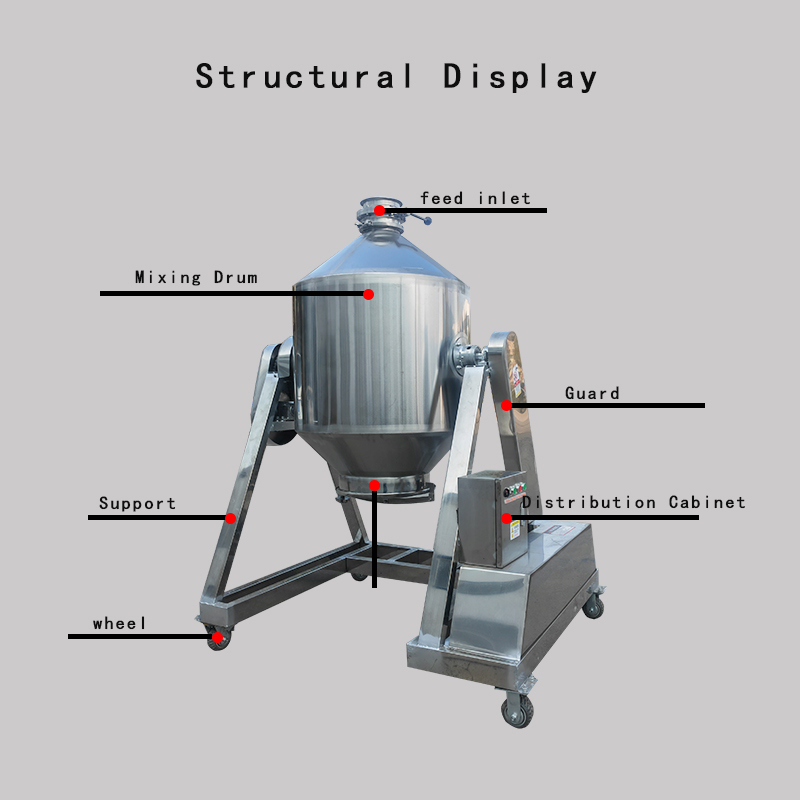

The Stainless Steel Flour Mixer is a drum-type mixer used for blending various powdered raw materials. This mixer offers a high degree of mixing uniformity. Its shape resembles a waist drum, hence it is also called a drum powder mixer or a double-cone powder mixer. Its vertical drum design, combined with specially shaped mixing blades, enables 360-degree dead-angle-free mixing, ensuring that the raw materials are thoroughly blended in a short time.

The Stainless Steel Flour Mixer rotates 360 degrees, tumbling and mixing. Mixing blades are located in the middle of the drum. During operation, the mixing blades rotate simultaneously. The rotating double-cone drum causes the materials inside to tumble and mix chaotically, while the high-speed rotating blades break up any clumps, allowing for rapid and homogeneous mixing within the drum.

Operating Procedures for the Stainless Steel Flour Mixer Pre-Production Preparation

Mixing Operation

A. Check that the drum outlet is closed and ensure it is securely shut. Check the direction of the inlet; the correct position is approximately 45 degrees upward. If it is not in the correct position, start the machine, rotate the drum to the correct position, and then stop the machine.

B. Loosen the fixing screw next to the outlet, open the outlet, and pour the prepared materials into the drum (volume should not exceed 2/3 of the drum’s capacity).

C. Close the outlet and tighten the fixing screw.Mixing:

Start the machine. Move the forward/reverse switch to the right to rotate the drum forward. Start the timer. Control the mixing time based on the volume of materials in the drum—typically 5-10 minutes of forward rotation. Then, return the switch to the center position to stop the drum. After the drum comes to a complete stop, move the switch to the left to rotate the drum in reverse for the same duration. Stop the machine, paying attention to control the drum’s final position so that the outlet faces downward.Applicable Materials

The Stainless Steel Flour Mixer can blend various powdered raw materials, including:

-Flour, rice flour

Spice powders

White sugar, granulated sugar, salt

Glutinous rice flour, pumpkin powder, dumpling flour

Chili powder, Sichuan pepper powder, pepper powder

Star anise powder, bay leaf powder, cumin powder, fennel powder

Starch

Monosodium glutamate (MSG), chicken bouillon powder Food additives

Fruit and vegetable powders, yam powder

Traditional Chinese medicine powders: Panax notoginseng powder, angelica powder, atractylodes powder

Barbecue seasonings, dipping and sprinkling mixes

Whole grain powders, meal replacement powders, nutritional powders

Lily bulb powder, red date powder

Mung bean powder, soybean powder

Nó cũng có thể trộn bột hóa chất, bột dược phẩm và các nguyên liệu thô khác.

Maintenance and Care

Daily Cleaning: Clean the mixing drum and blades after each use to prevent material residue and bacterial growth.

Regular Inspection: Periodically check if the tightening screws on the mixing blades are loose and if the belt tension is appropriate.

Gearbox Lubrication: Regularly change or add the specified food-grade lubricant to the reduction gearbox according to the manufacturer’s manual.

Professional Service: If abnormal noise or vibration occurs, stop the machine immediately and have it inspected by qualified personnel.

Máy xay hạt ca cao thích hợp cho chế biến sô cô la, thực phẩm và đồ uống, mang lại hiệu suất cao, kích thước hạt đồng đều và hỗ trợ dây chuyền sản xuất.

Xem chi tiếtMáy trộn tinh bột ngô dùng để trộn đều và xử lý bột hiệu suất cao trong các dây chuyền sản xuất thực phẩm, hóa chất và dược phẩm.

Xem chi tiếtMáy trộn bột sữa đảm bảo trộn đều và sản xuất hiệu quả cao, lý tưởng cho các dây chuyền sản xuất sữa, thực phẩm và bột dinh dưỡng.

Xem chi tiếtMáy trộn bột phòng thí nghiệm dùng cho thử nghiệm quy mô nhỏ, R&D và sản xuất thử nghiệm, cung cấp khả năng pha trộn đồng đều và ứng dụng linh hoạt.

Xem chi tiếtTrang web này sử dụng cookie để cải thiện trải nghiệm duyệt web của bạn. Bằng việc tiếp tục sử dụng trang web này, bạn chấp nhận việc sử dụng cookie của chúng tôi. Dữ liệu thu thập từ trang web này được xử lý và lưu trữ tại Hoa Kỳ.