Ribbon Type Dry Powder Mixer

1896Ribbon type dry powder mixer for uniform blending of powders in food, chemical, and pharmaceutical industries, enhancing production efficiency.

View detailsSearch the whole station

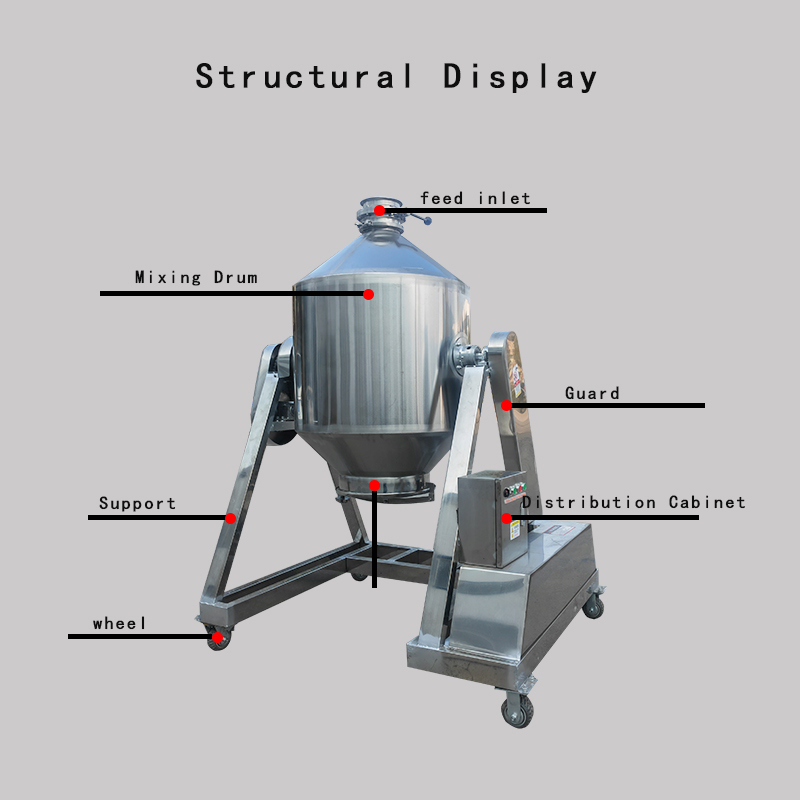

The milk powder drum mixer is an efficient equipment specially designed for mixing milk powder and related powdery materials. It is widely used in the food, pharmaceutical, chemical and other industries for mixing processing of milk powder with other powders and small amounts of liquids. With its unique drum rotation structure, materials are fully tumbled in a closed cylinder to achieve fast and uniform mixing.

The milk powder drum mixer is mainly composed of a drum-shaped cylinder, a rotary drive device, and a feeding/discharging mechanism. During operation, the drive device drives the drum-shaped cylinder to rotate, and the materials in the cylinder move circularly with the cylinder and continuously tumble and diffuse, so that different materials are mixed evenly.

Ribbon type dry powder mixer for uniform blending of powders in food, chemical, and pharmaceutical industries, enhancing production efficiency.

View detailsComplete spice crushing line for high-efficiency processing, uniform particle size, and optimized production in food and seasoning industries.

View detailsCorn starch mixer for uniform blending and high-efficiency powder processing in food, chemical, and pharmaceutical production lines.

View detailsFlour mixer made of stainless steel for uniform and efficient powder mixing, supporting bakery, food, and chemical production lines.

View detailsThis website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.