Efficient Grain Grinder – Easy Milling of Cereals

1317Grain grinder for efficient milling of cereals and grains, ensuring uniform particle size and supporting food processing and feed production lines.

View detailsSearch the whole station

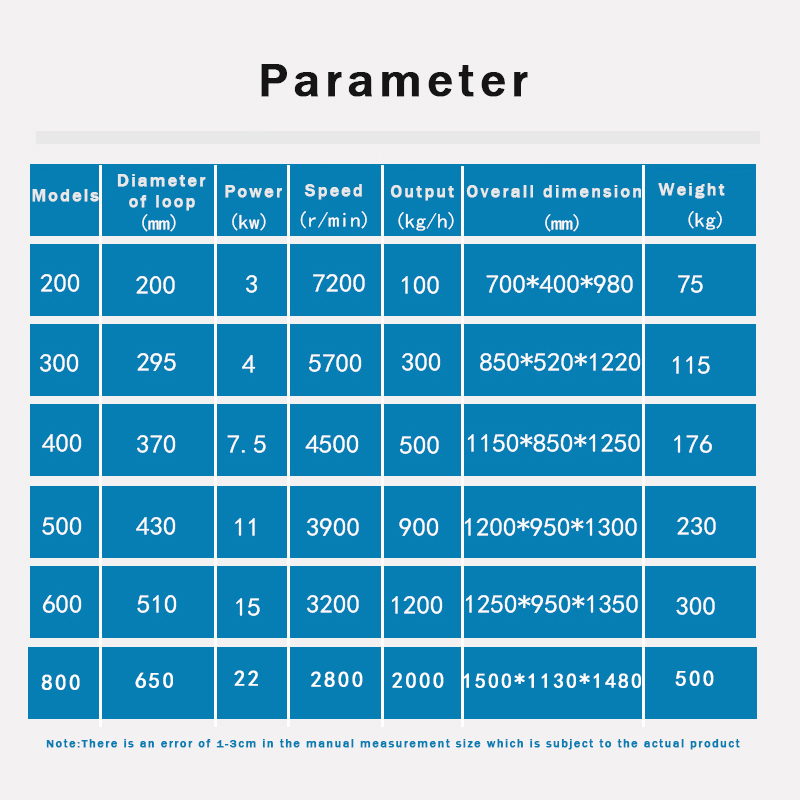

The Stainless Steel Cinnamon Grinder is a large-scale spice grinding machine, specifically a fine crusher. Equipped with a stainless steel pulse dust collector at the rear, it can also be called a pulse dust collection grinder, offering excellent dust removal效果. It supports continuous operation, and the fineness of the grind is adjustable by changing the screen. It is suitable for pharmaceuticals, food, chemicals, metallurgy, geology, agriculture, scientific research institutions, and other units for the grinding processing of valuable medicinal herbs and chemical raw materials.

The Stainless Steel Cinnamon Grinder mainly consists of the grinder host, dust removal pipe, cyclone dust removal, pulse dust removal, and a centrifugal high-pressure fan. The motor is a pure copper motor with strong power; an explosion-proof motor can also be configured for safer production. Based on the ordinary single machine, the Stainless Steel Cinnamon Grinder adds a cyclone dust removal device, making it more environmentally friendly for materials that produce higher dust, with no dust emission.

The Stainless Steel Cinnamon Grinder pulverizes materials using the internal fixed and movable toothed discs. The working principle involves the toothed discs starting to rotate at high speed driven by the motor. Material enters the grinding chamber evenly through the feed hopper, where the high-speed rotating discs carry out the rotational crushing work. Once the desired fineness is achieved, the finished product is discharged through the screen base at the discharge hopper. A airlock feeder above the discharge port allows for windless and dust-free free-fall discharge. The rear pulse dust collector can also absorb micro-dust generated during operation into the dust collection box. The grinding fineness is adjustable from 10 mesh to 120 mesh. The fineness varies depending on the raw material and can be selected as needed.

The Stainless Steel Cinnamon Grinder first performs coarse crushing before the material enters the fine crusher for grinding. This grinder can crush:

Chili peppers, Sichuan peppercorns, black pepper, star anise, cumin, fennel, cardamom, nutmeg, tsao-ko, cloves, rosemary, coriander seeds, dried ginger, turmeric, white pepper, black pepper, dried garlic slices, compound seasonings, monosodium glutamate (MSG), chicken bouillon, salt, sugar, caked brown sugar, salt, rice, corn, starch, oats, flour, soybeans, peas, lentils, mung beans, spices, flavorings, sweeteners, dried fruits, nuts, potato chips, bread crumbs, cocoa powder, potato powder, coffee, milk powder, onions, dehydrated vegetables, lotus seeds, glucose, oat hulls, nut shells, and other materials.

Important Notes for the Stainless Steel Cinnamon Grinder:

Grain grinder for efficient milling of cereals and grains, ensuring uniform particle size and supporting food processing and feed production lines.

View detailsCorn starch mixer for uniform blending and high-efficiency powder processing in food, chemical, and pharmaceutical production lines.

View detailsSugar grinders enabling flexible milling from coarse sugar to icing sugar, improving efficiency and uniformity in confectionery and food production.

View detailsMilk powder mixer ensuring uniform blending and high-efficiency production, ideal for dairy, food, and nutritional powder lines.

View detailsThis website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.